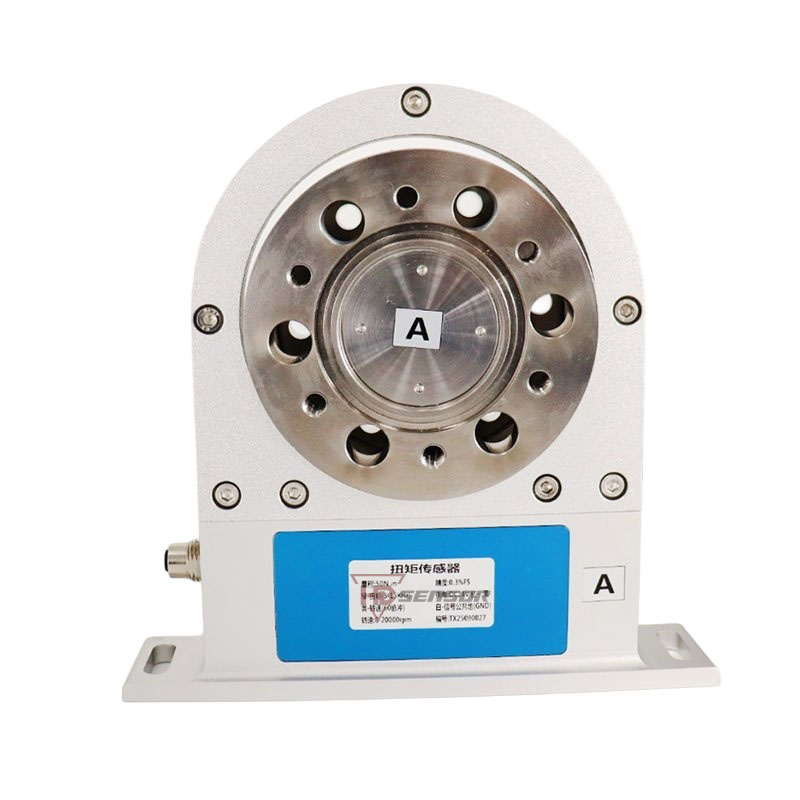

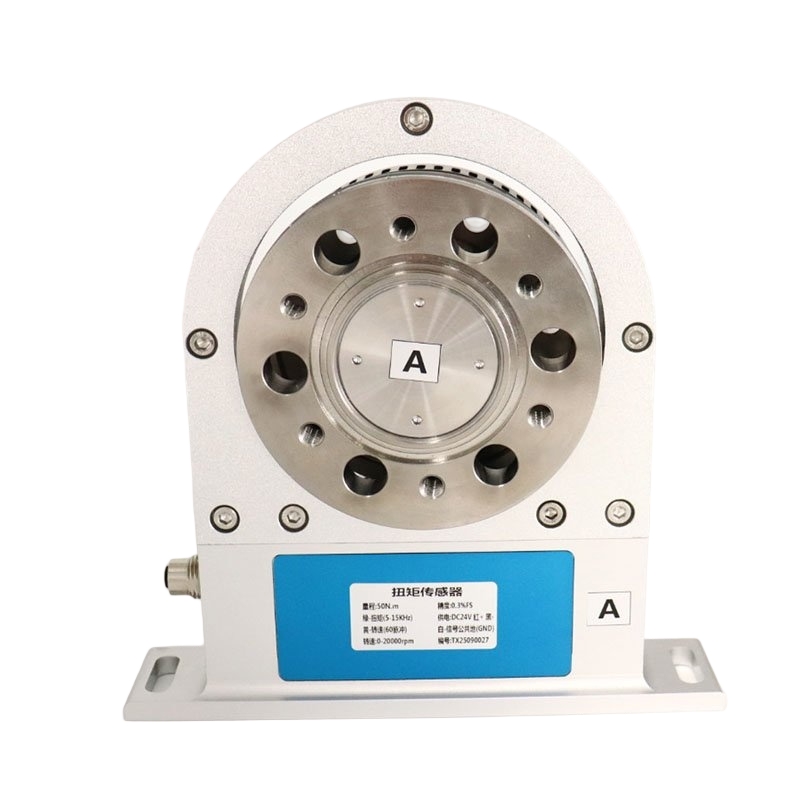

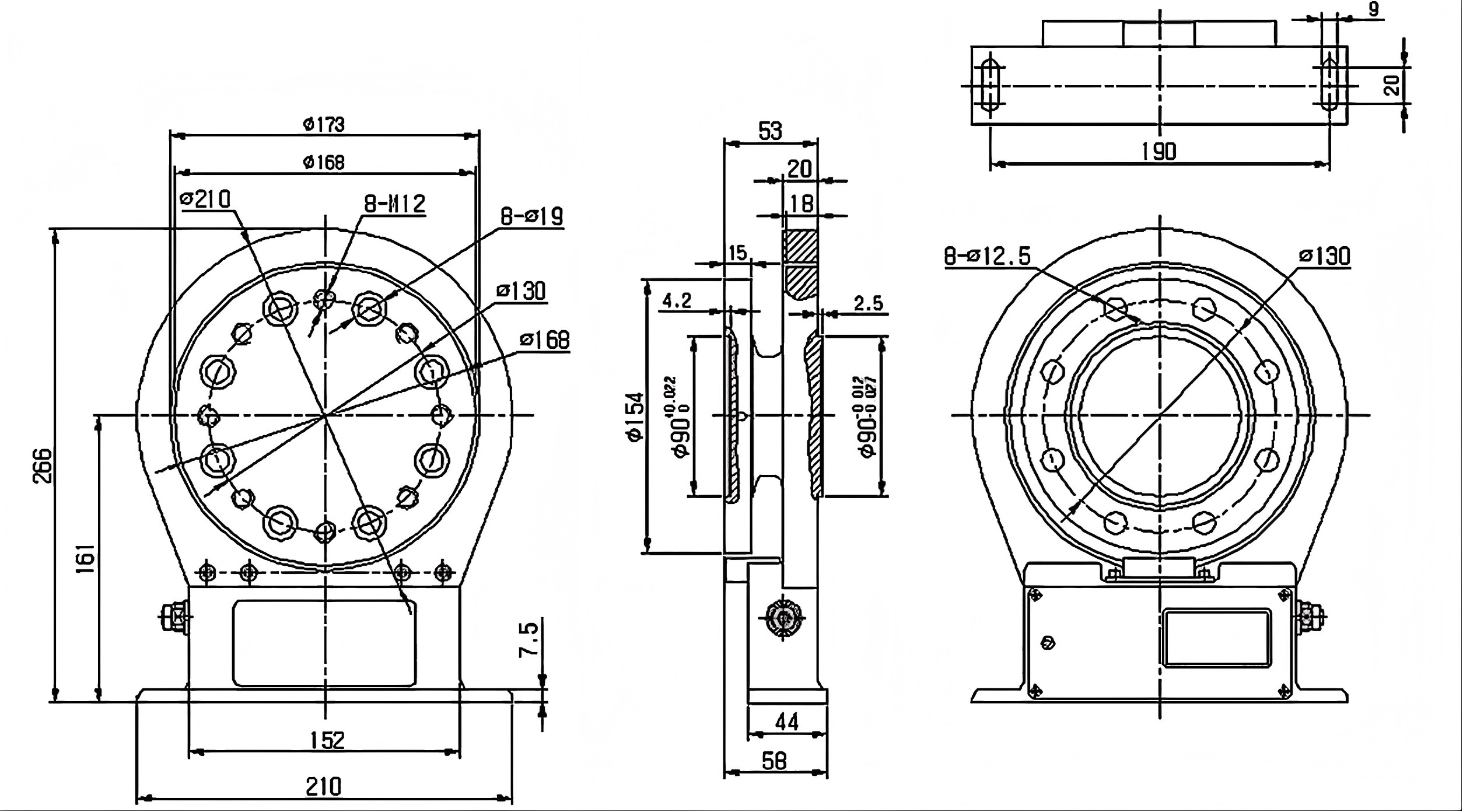

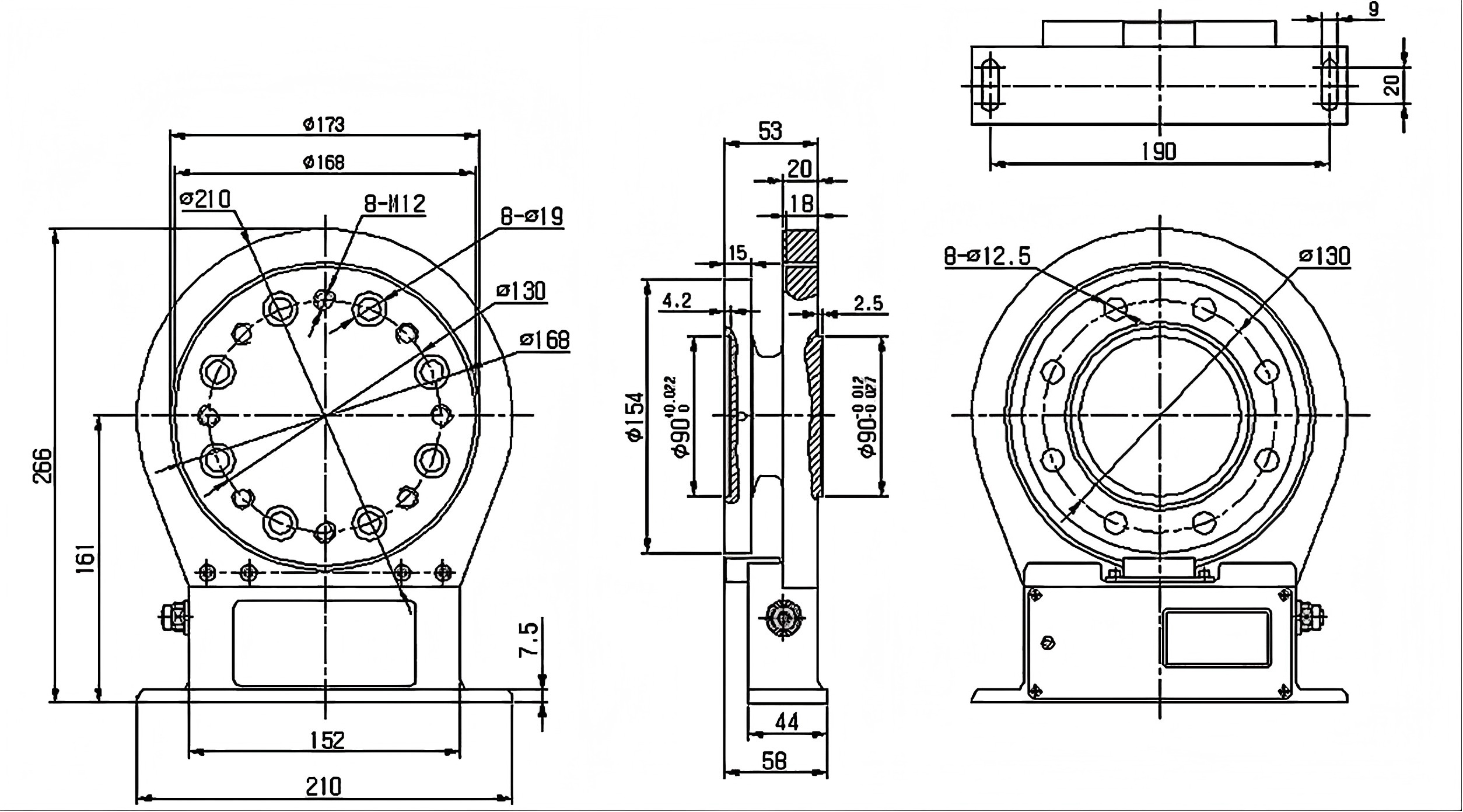

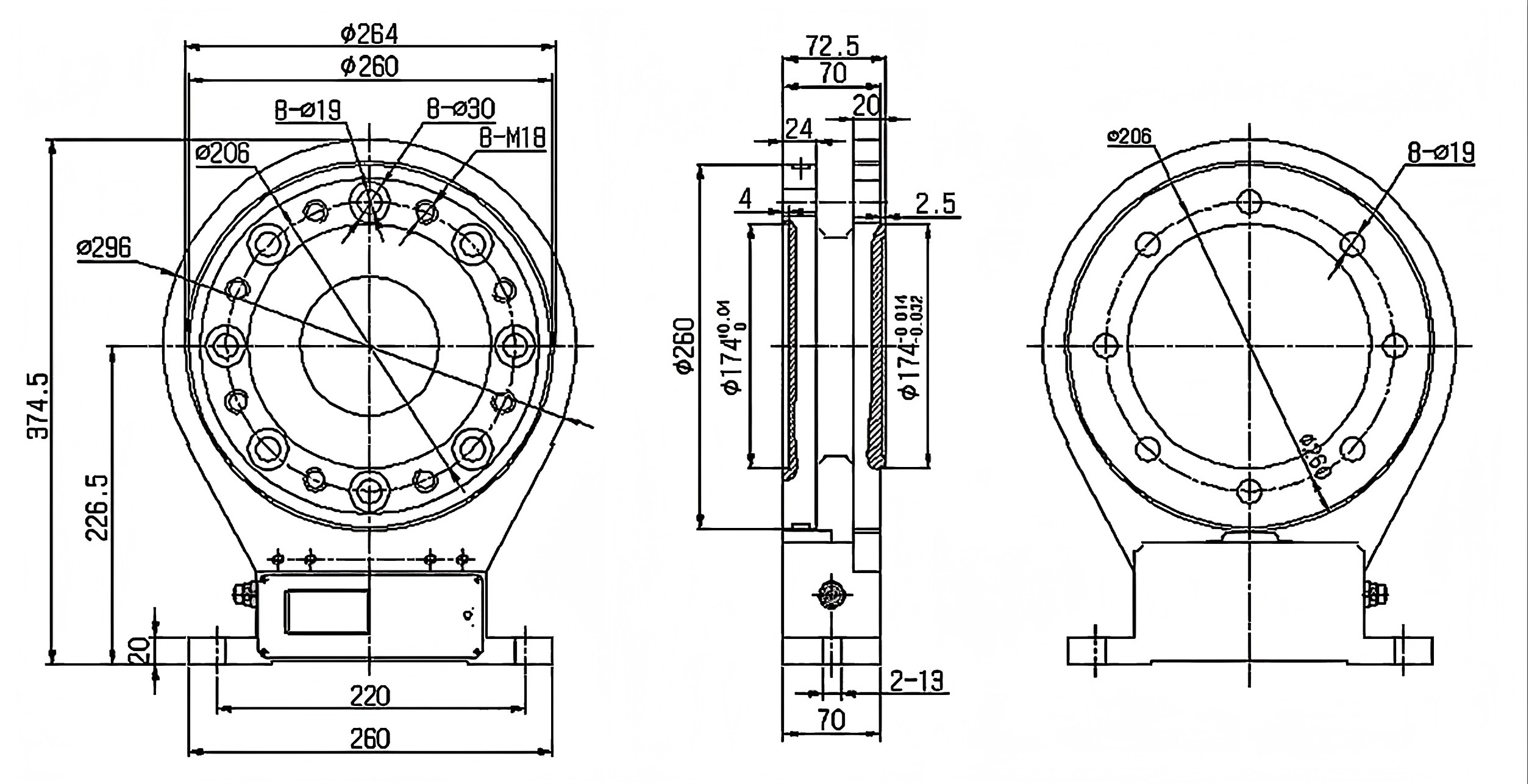

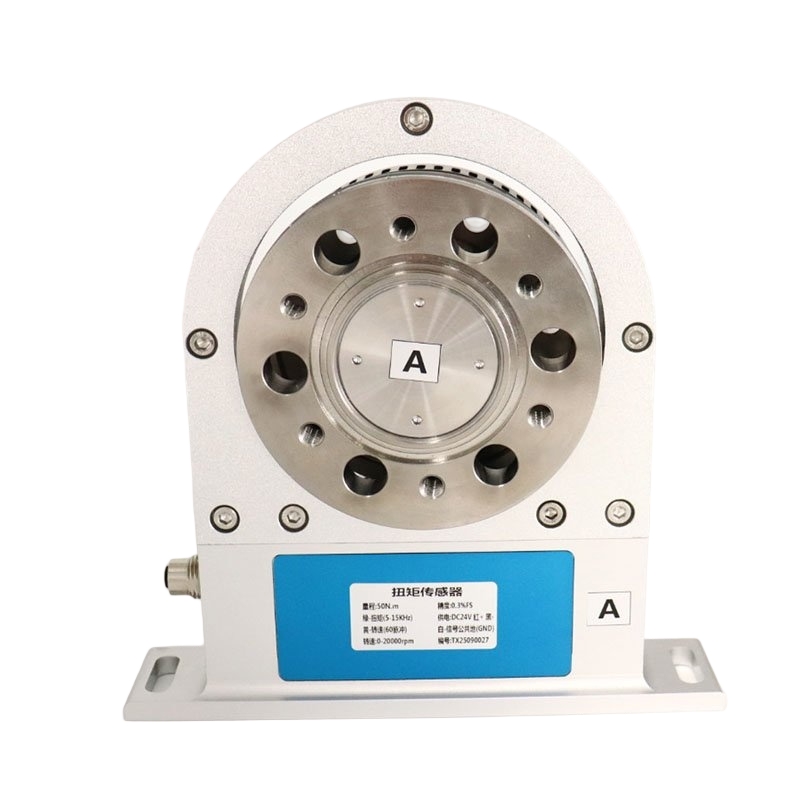

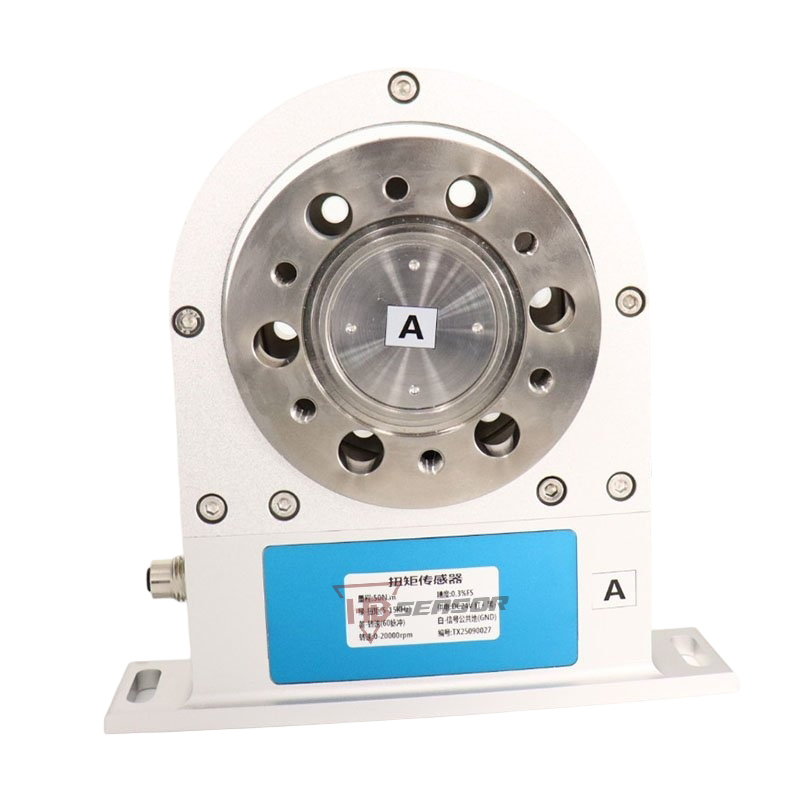

HaiboSensor model HBTLWQNLD -A is a high-precision Rotary dynamic torque sensor with a bearingless flange disc design, developed specifically for challenging environments requiring accurate measurements. It performs exceptionally well in capturing torque and rotational speed data at high speeds and with great accuracy, and provides adaptable output interfaces for effortless integration into various testing systems.

Key Features & Advantages

The working principle of the Rotary torque sensor :Torque measurement is achieved through strain gauge-based electrical detection. A Wheatstone bridge configuration is established on the elastic shaft, and by supplying power to this bridge circuit, the electrical response corresponding to the torsional deformation can be captured. The acquired signal is then amplified and converted from voltage to frequency, resulting in an output signal whose frequency is directly proportional to the applied torsional strain.

The disc-Rotary type torque sensor is a precision measurement device capable of contactless detection of multiple parameters, including torque, rotational velocity, and mechanical power.Experience the accuracy and dependability of HAIBO Rotary Torque Sensors. Our product line includes a wide selection of models with various capacity ranges, designed to suit the unique demands of different applications. Tailored configurations can be provided, covering adjustments in external dimensions, rated load capacity, material choices, and compatibility with numerous signal processing units, display devices, and digital data collection tools.

For those seeking a rotary torque sensor that delivers superior performance, long-lasting durability, and measurement precision, reach out to the HAIBO team now to schedule a professional consultation.

Our Haibosensor rotary torque sensor utilizes a advanced disc-style sensing element instead of a traditional tubular shaft. This design provides several distinct advantages for demanding industrial and R&D applications.

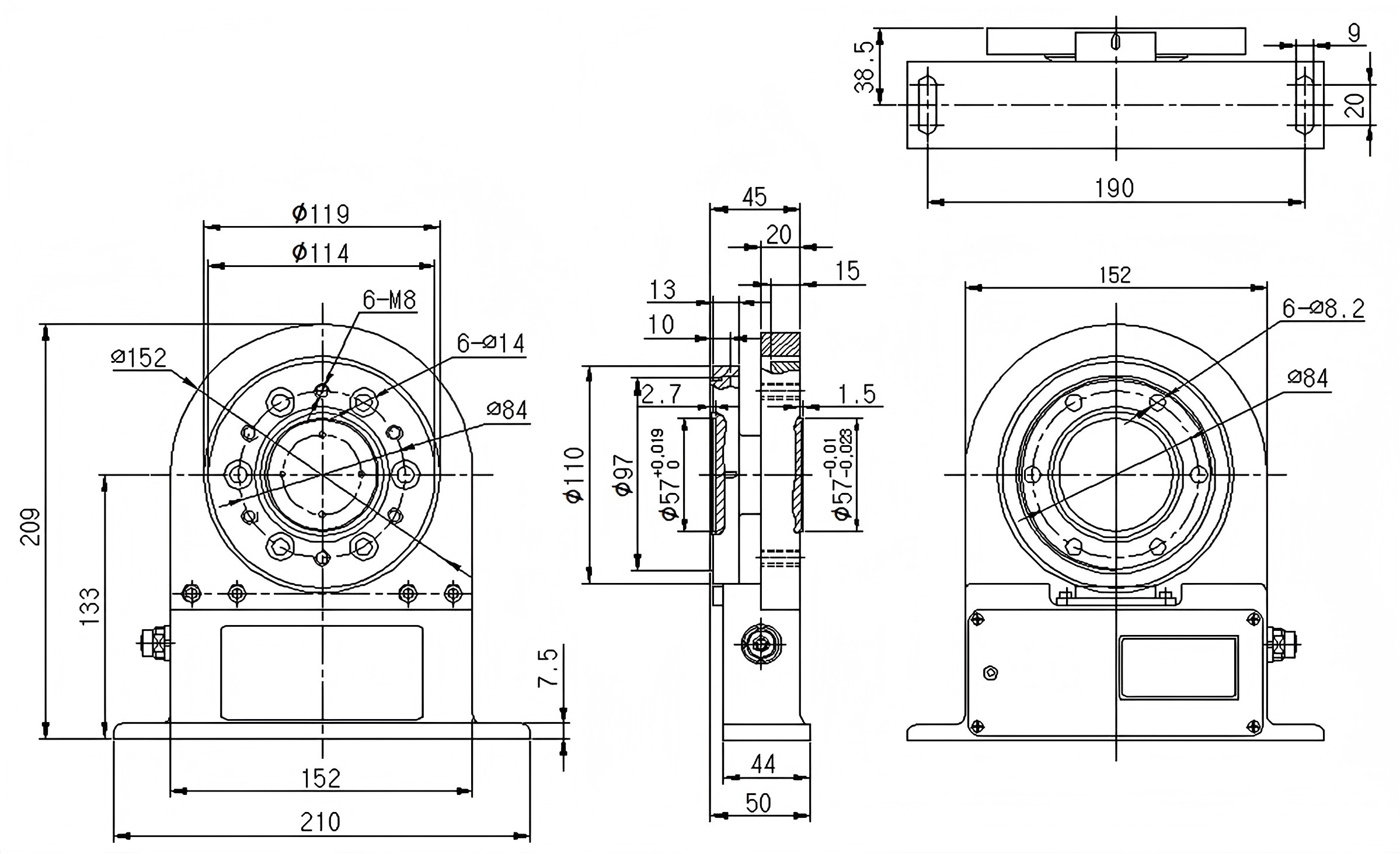

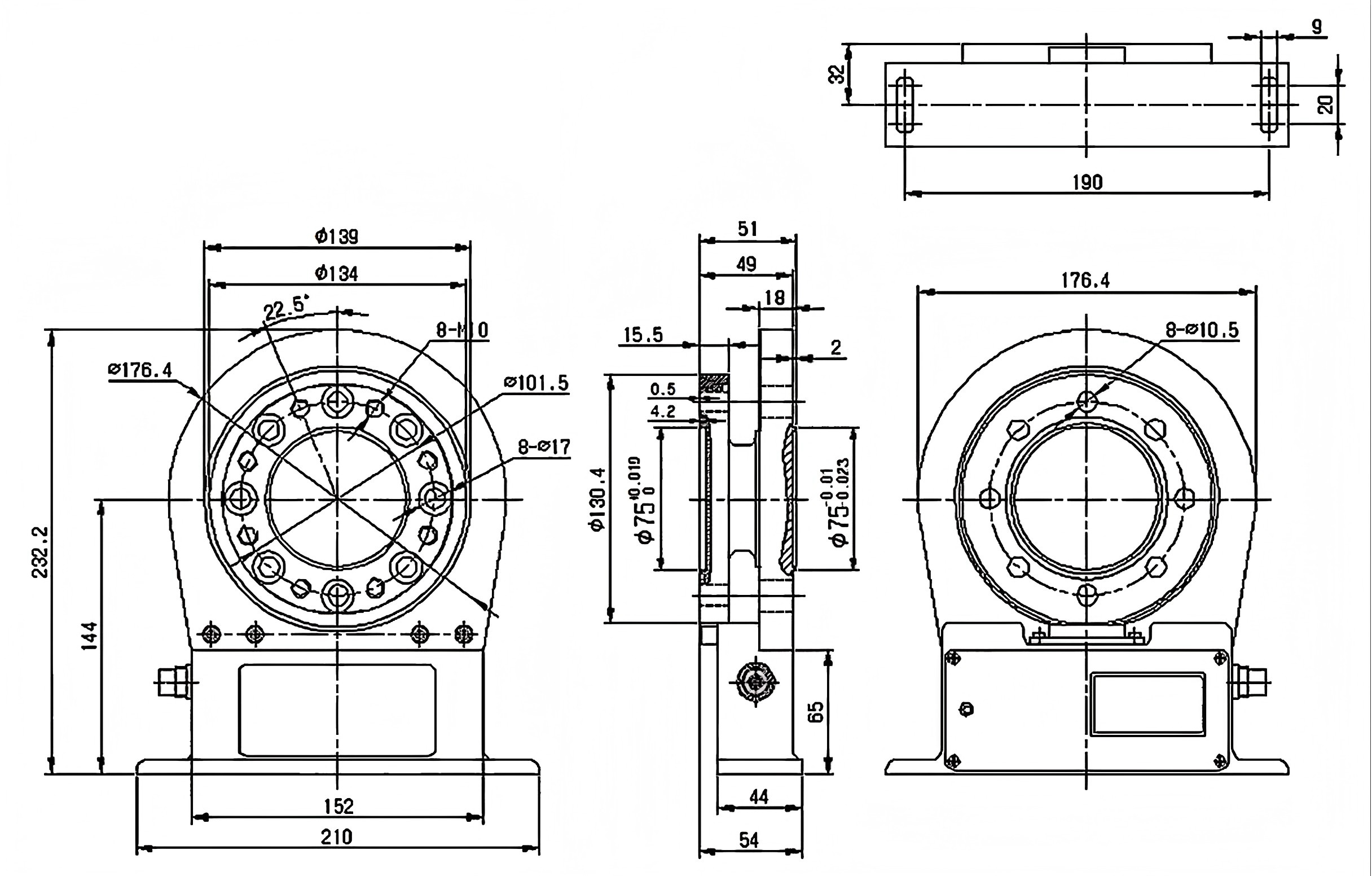

The flat, pancake-like form factor offers an exceptionally short axial length, allowing for installation in extremely confined spaces.

The monolithic disc is machined from a single piece of high-strength alloy, providing extremely high torsional stiffness.

This results in a very high natural frequency, allowing the sensor to accurately capture fast torque transients and dynamic events without resonance.

The disc-style element operates without any bearings. This eliminates a major source of friction, wear, and maintenance, ensuring long-term reliability and measurement stability.

Features integrated mounting flanges on both sides for a direct, rigid connection to the driver and driven units.

Precision strain gauges are strategically applied to the optimized disc structure. This design maximizes sensitivity to torque while effectively rejecting extraneous loads like bending moments and axial forces.

This design provides excellent resistance to misalignment loads (coaxiality error), protecting the sensitive sensing element and ensuring measurement accuracy.

| Output Type | Sub-Type | Description & Specifications |

|---|---|---|

| Pulse | Open Collector (NPN) | • Type: NPN open collector. Requires an external pull-up resistor (R). • Voltage/Resistor: 5V (R=330Ω-1kΩ), 12V (R=2kΩ-4.7kΩ), 24V (R=10kΩ-20kΩ). • Default Frequency: Torque: 10±5 kHz; Speed: 0-30 kHz (60 pulses/rev, 1 kHz = 1000 RPM). • Custom frequencies available upon order. |

| Push-Pull | • Type: Push-Pull (Totem Pole) output. • Voltage: High level defaults to +5V (+12V available upon request). • Default Frequency: Torque: 10±5 kHz; Speed: 0-30 kHz (60 pulses/rev, 1 kHz = 1000 RPM). • Custom frequencies available upon order. | |

| Differential Line Driver | • Type: Differential output using AM26LS31 chip. Recommended receiver: AM26LS32. Can also drive an optocoupler directly. • Default Frequency: Torque: 10±5 kHz; Speed: 0-30 kHz (60 pulses/rev, 1 kHz = 1000 RPM). • Custom frequencies available upon order. | |

| Analog Voltage | — | • Range: 0 to ±10 VDC, user-definable within full scale. • Default: Torque: 0 ±10 VDC; Speed: 0 – 10 VDC. |

| Analog Current | — | • Range: 0-20 mA, user-definable within full scale. • Default: Torque: 4-12-20 mA; Speed: 4-20 mA. |

| Communication | RS485 | • Supported Baud Rates (bps): 115200 (default), 57600, 38400, 19200, 9600, 4800, 2400. |

| RS232 | • Supported Baud Rates (bps): 115200 (default), 57600, 38400, 19200, 9600, 4800, 2400. | |

| CAN | • Supported Baud Rates (bps): 1M (default), 500K, 250K, 100K, 50K, 10K, 1K. | |

| Power Supply | • Default: 24 VDC (±10%), Max. current consumption: 150 mA. • Optional: 12 VDC (±10%) available upon order, Max. current consumption: 300 mA. |

Torque Sensor Display Instrument Digital Monitor LCD is a torque measurement device that can be connected to both dynamic and static torque sensors for testing

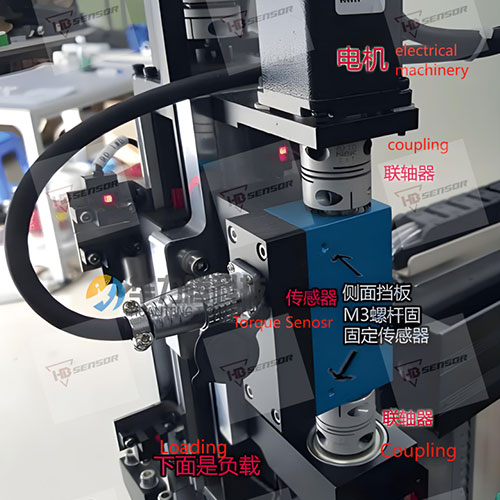

1. Measuring the output torque and power of rotating power sources such as electric motors, engines, and internal combustion engines;

2. Assessing the torque and power levels of equipment like fans, water pumps, gearboxes, and torque wrenches;

3. Monitoring torque and power in transportation and heavy machinery, including railway engines, automobiles, tractors, aircraft, ships, and mining equipment;

4. Evaluating torque and power performance in wastewater treatment systems;

5. Supporting the development and calibration of viscometers;

6. Serving various applications in process and continuous flow industrial systems.

Are you a factory? Do you have certification documents? Certainly, we possess relevant certificates, including ISO 9001, ROHS, CE, OIML, and CE certifications. Indeed, we operate as a factory with extensive technical expertise in the specialized production of force and rotary torque sensors over many years. You are welcome to consult us free of charge regarding any technical issues.

Rotary torque sensor

Free Sensor Sizing & Consultation. Message us your torque range, speed, and desired output. Our engineers will ensure a perfect fit for your system

Customized to Your Needs. Select your options (Torque, Speed, Output) and request a quote today

Need help selecting the right output? Tell us your application (e.g., motor test, PLC), and we’ll recommend the best model. Get your personalized quote in 24 hours.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.