Haibosensor is a professional manufacturer of foil strain gauges, offering high-precision force sensors and load cells for diverse industrial applications.

With extensive experience in strain gauge production, we provide customized solutions tailored to specific client needs, including unique designs and technical support.

Haibosensor also offers free samples for evaluation, ensuring product compatibility and performance. Their foil strain gauges feature excellent sensitivity, stability, and durability, suitable for stress analysis, load testing, and structural monitoring.

Contact Us

Products

Blogs

Strain gauges (sometimes referred to as strain sensors) are sensors whose resistance varies with the applied force. They can convert physical quantities such as force, pressure, tension, and weight into changes in resistance, thereby enabling the measurement of these physical quantities. As one of the most crucial sensors in electrical measurement technology, strain gauges are primarily used for measuring mechanical quantities.

HAIBOSENSOR is a factory specializing in the production of strain gauges. We have professional engineers who can provide customized services such as helping you with model selection, glue selection, and strain – gauge bonding methods, enabling your products to achieve intelligent upgrading in weighing.

Strain gauges are arranged in various orientations based on the kind of force to be measured. Specific configurations of strain gauges are used to measure bending strain, shear strain, axial strain, torque, and pressure respectively.

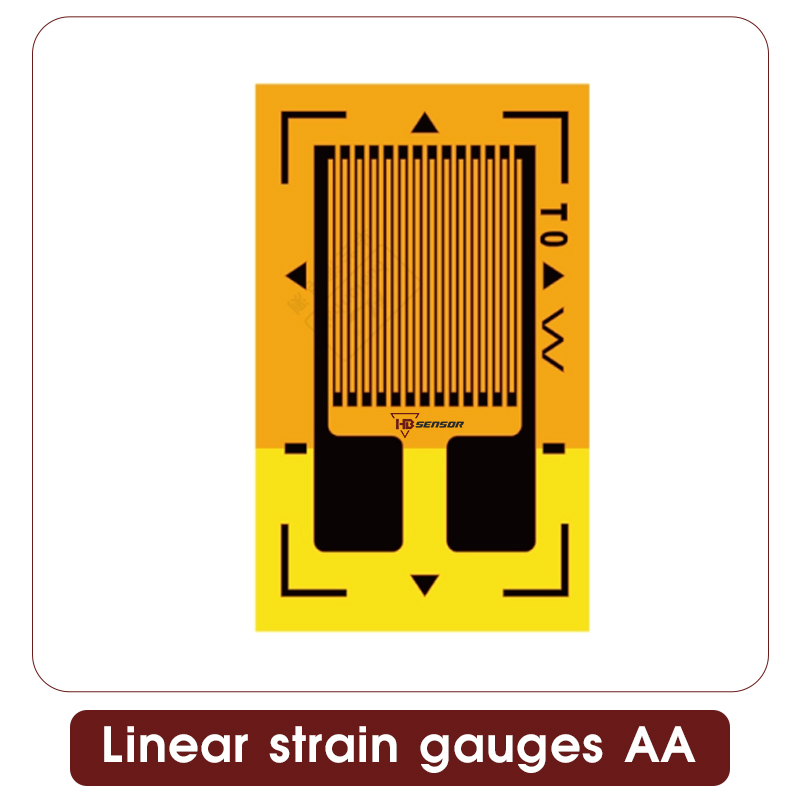

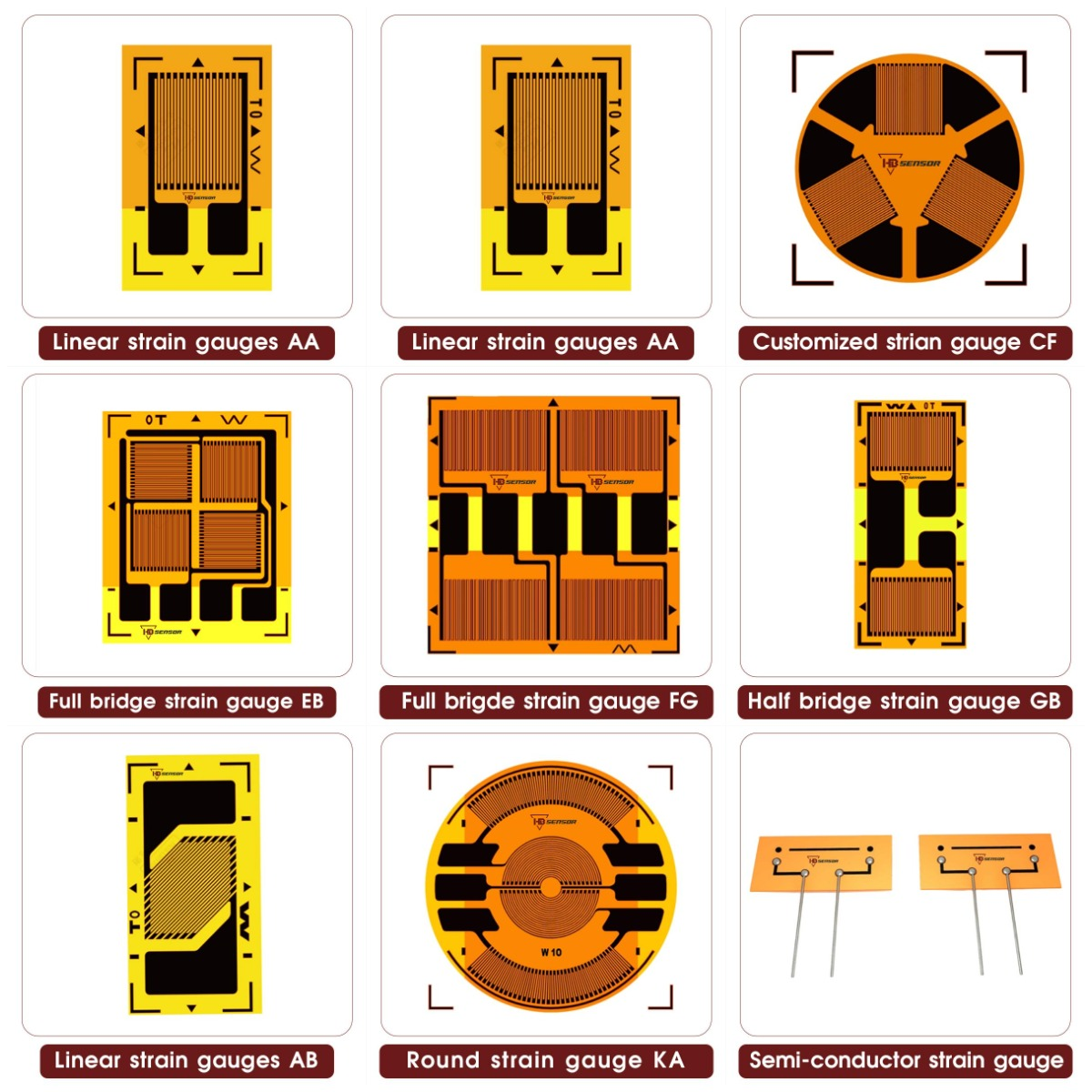

Linear strain gauges feature a single measuring grid and are designed to detect strain in only one direction, making them suitable when analysis in a single axis is required.

Double linear strain gauges consist of two parallel measuring grids. These strain gauges are commonly used in load cells and are ideal for applications such as measuring strain on bending beams, testing ship hulls and structural parts, vehicle testing, construction, railway systems, and aerospace engineering.

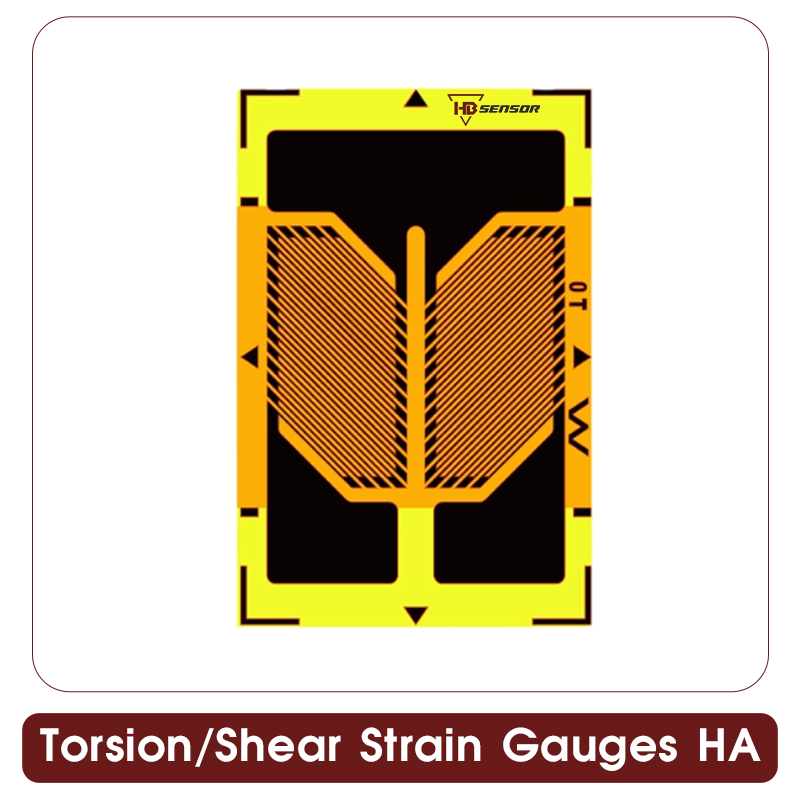

Shear strain gauges, often shaped like a “V,” contain two measuring grids positioned at a 90° angle relative to each other. These gauges are typically used for measuring strain on torsion bars and for determining shear stresses found in shear beams, particularly in the region of neutral fibers.

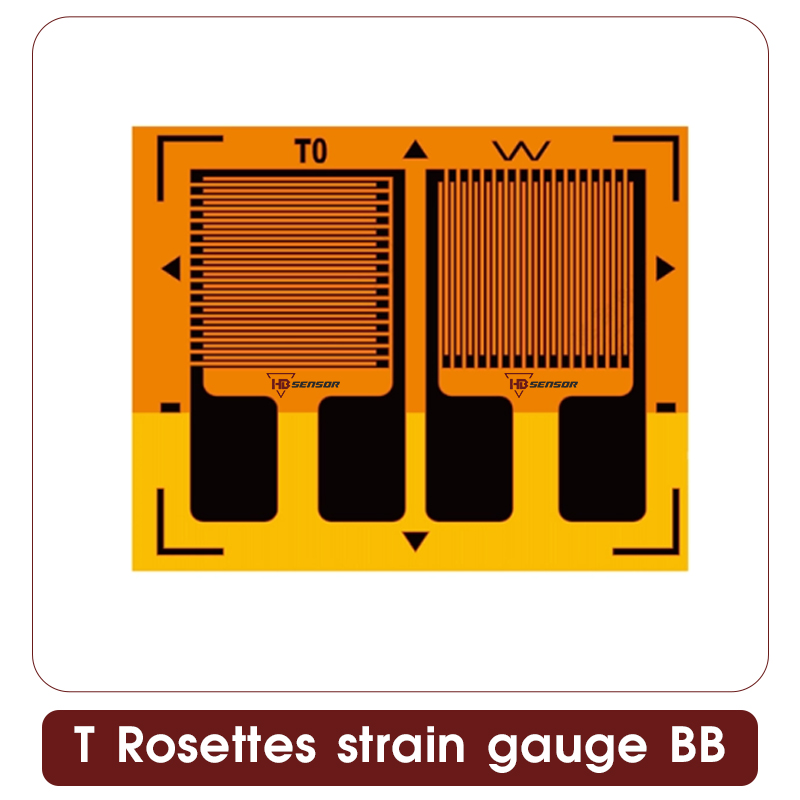

Right-angle strain gauges, also known as T-rosettes, have two measuring grids oriented at a 90° angle apart. This type is commonly used for evaluating biaxial stress states where the principal directions are known, as well as for strain measurements on tension and compression bars.

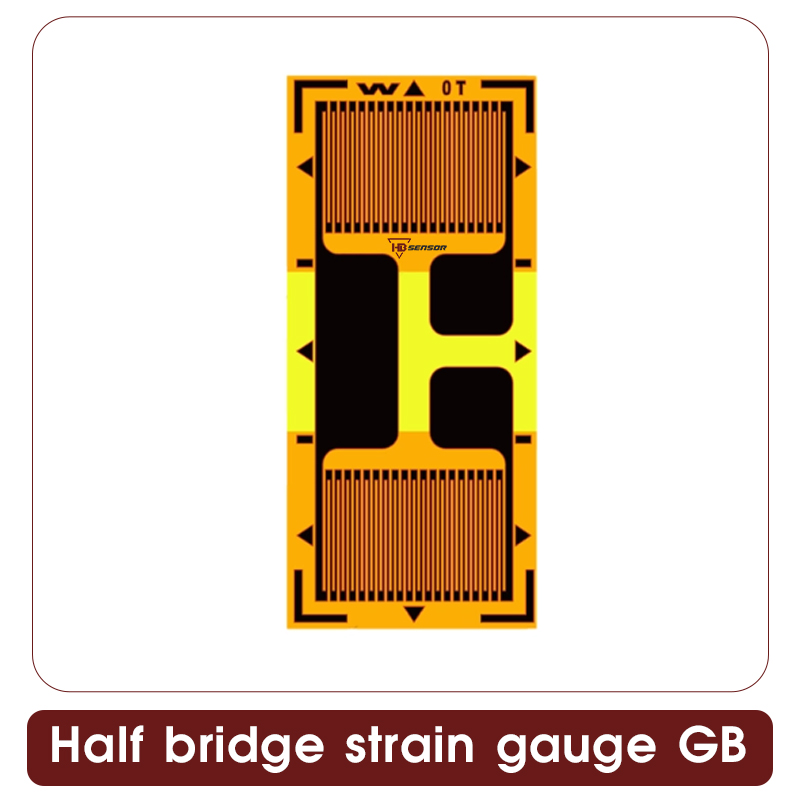

Half-bridge strain gauges are specifically designed for producing high-precision load cells based on the bending beam principle. They are particularly useful in situations where space constraints limit the length of the beam.

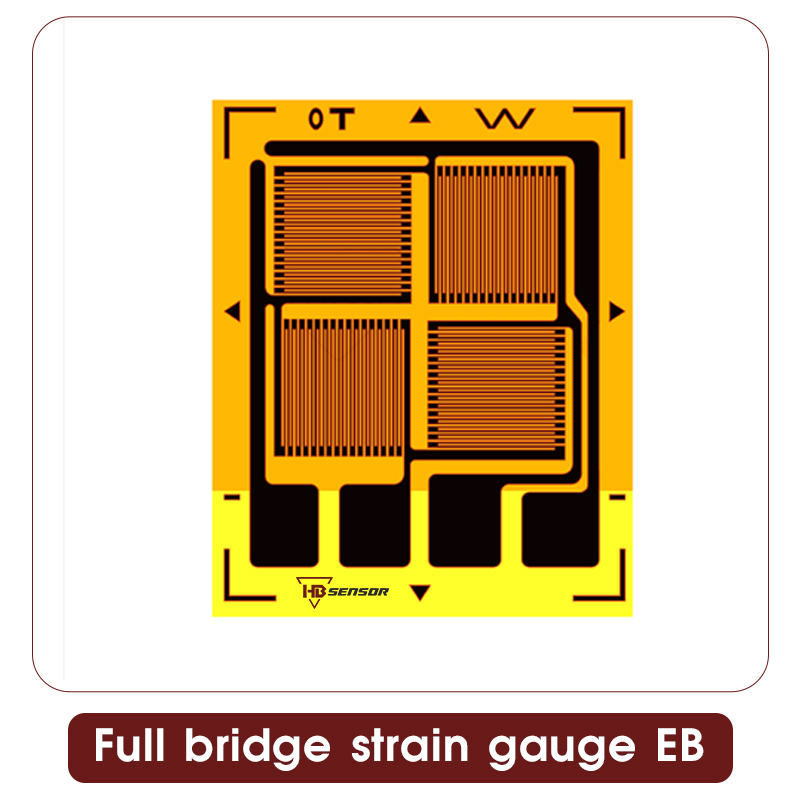

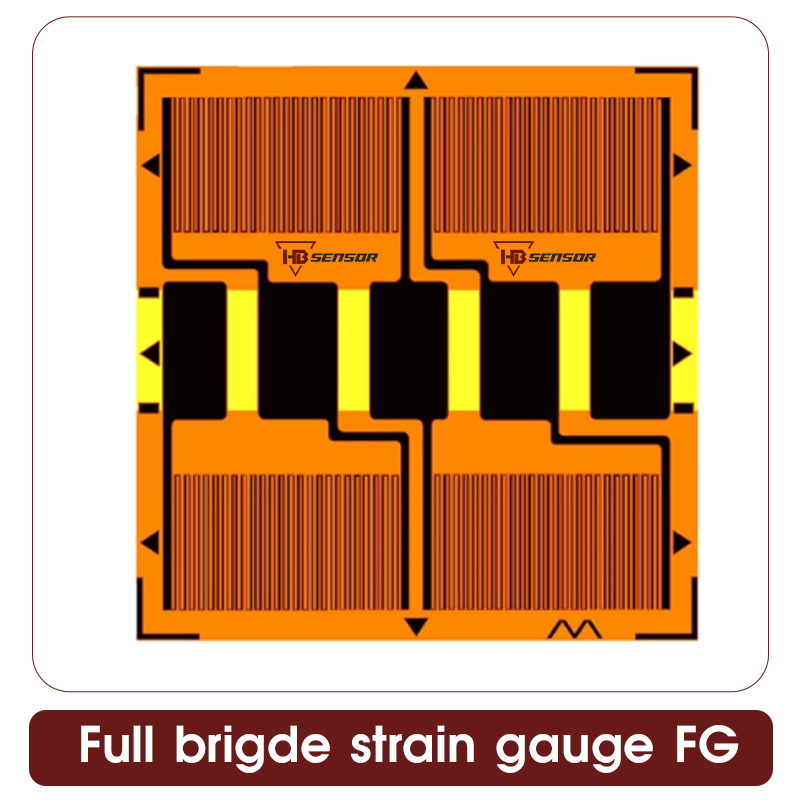

Full-bridge strain gauges incorporate four measuring grids, each spaced 90° apart. These gauges are widely used for strain measurements on tension and compression bars and for determining shear stresses in shear beams.

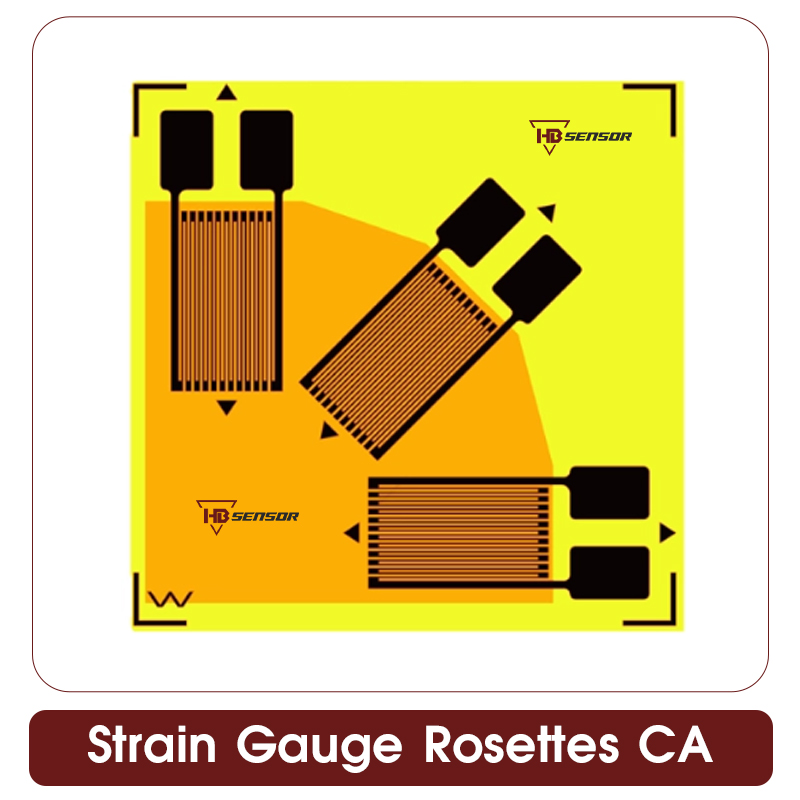

Rosette strain gauges consist of three measuring grids positioned at angles of either 0°/45°/90° or 0°/60°/120°. These strain gauges are ideal for analyzing biaxial stress states when the principal directions are not known in advance.

✔ Suitable for single point (shear beams,bending beam,load cells.

✔ High sensitivity & accuracy

✔ Good temperature stability

✔ Compatible with Wheatstone bridge circuits

Classic type model:BF35-3AA-TO

✔ Suitable for single point (shear beams,bending beam,load cells.

✔ High sensitivity & accuracy

✔ Good temperature stability

✔ Compatible with Wheatstone bridge circuits

✔ Suitable for shear-dominant load cells ( shear beams).

✔Torque Sensors (Combined Load & Torque Measurement)

✔ Dual-Bending (Double-Ended Shear Beam) Load Cells

✔ Suitable for shear-dominant load cells ( shear beams,torque Sensors ,dual-bending cantilever LOAD Cell)

✔ Temperature compensation .

✔ Simpler wiring compared to full-bridge setups.

✔ Good sensitivity for bending & shear-based load cells.

✔ Cost-effective for mid-precision applications

✔ Suitable for Torque-Load Combination Sensors,Shear Beam,S type,Rotary Weighing Load Sensor.

✔ Measures shear strain directly.

✔ Compensates for off-axis loading

✔ Robust in dynamic environments (e.g., vibrating/moving systems).

✔ Often used in full-bridge setups for high sensitivity.

✔ Suitable for Torque-Load Combination Sensors,Shear Beam,S type,Rotary,Button, Weighing Load Sensor.

✔ Highest sensitivity & output signal

✔ Automatic temperature compensation

✔ Cancels bending & axial interference

✔ Better noise immunity & long-term stability.

✔ Suitable for Single Point Load Sensors,Shear Beam,S-type,,Button,Column Weighing Load Sensor.

✔Industries Using GB Full-Bridge Gauges

✔Industrial Weighing (tanks, hoppers, process control).

✔Precision Measurement (laboratory balances, medical devices).

✔Aerospace & Automotive (structural testing, torque/force sensors).

✔ Suitable for Single Point Load Sensors,Shear Beam,S-type,,Button,Column,Thin-Flexure Load Cells Weighing Load Sensor.

✔ Measures multi-directional strains (0°/45°/90° or 0°/60°/120°).

✔ Identifies principal stress directions (critical for complex loading).

✔ Compensates for off-axis loading errors (improves accuracy).

✔ Suitable for dynamic & non-uniform stress fields.

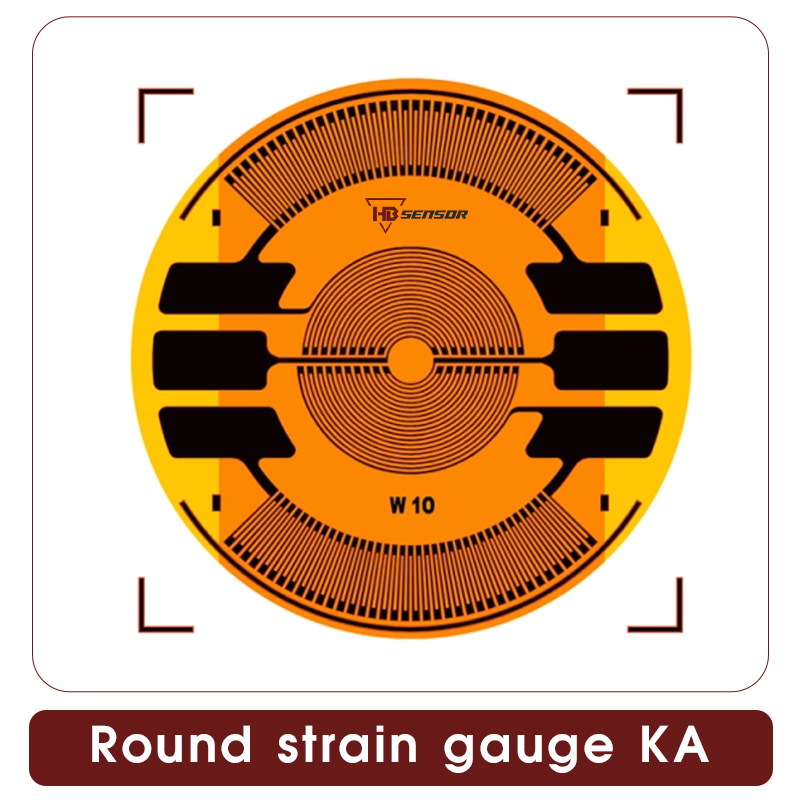

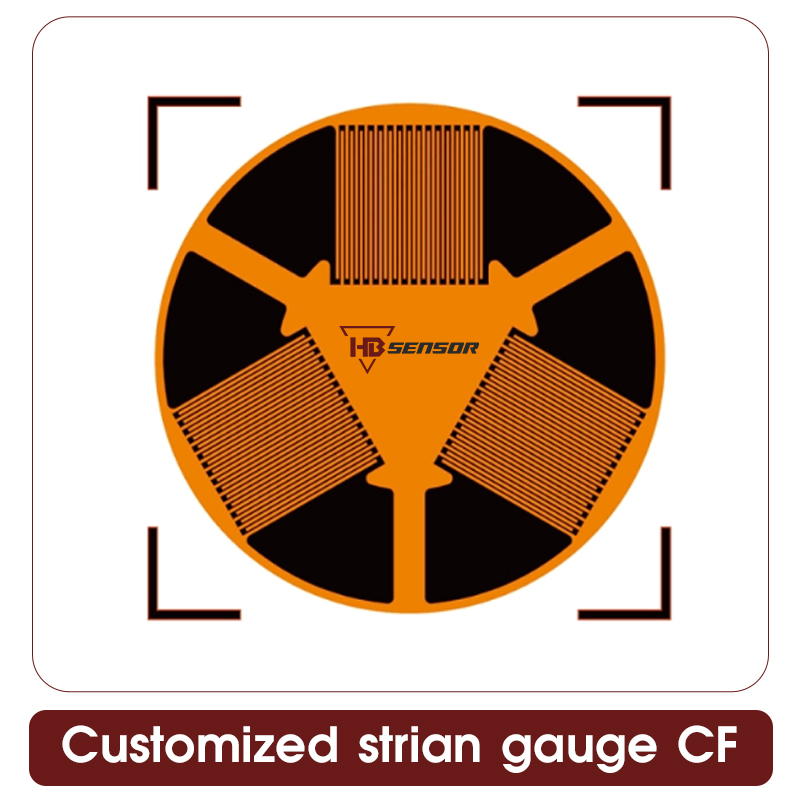

✔ Suitable for Torque Sensors ,Ring-Type ,Pressure Sensor,Canister

Bending-Compression Hybrid Load Cells,Medical Force Sensors.

✔ Optimized for radial/hoop strain measurement

✔ Flexible mounting on curved surfaces

✔ Reduced sensitivity to alignment errors

✔ Effective in torsional/shear applications

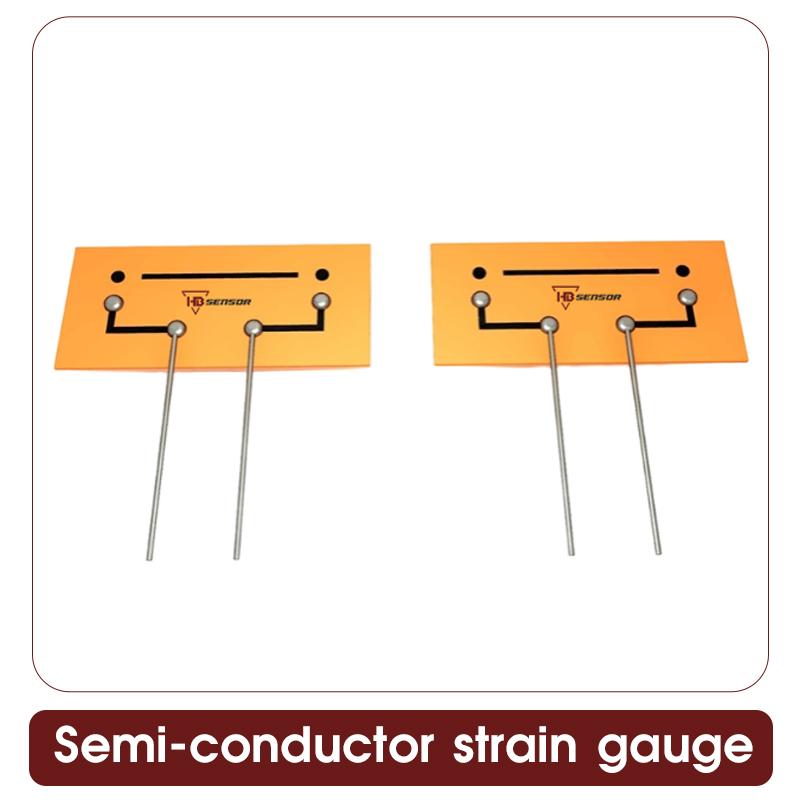

✔ Suitable for Micro Load Cell,High Precision Micro Pressure Sensor,Dynamic Force Sensor,Semiconductor-Based Torque Sensors.

✔ Extremely high gauge factor (50-200 vs. 2-5 for metal gauges) – Great for weak signals.

✔ Miniaturization – Can be integrated into ICs or microstructures.

✔ Fast frequency response – Suitable for dynamic measurements.

✔ Suitable for Single Point Load Sensors,Shear Beam,S-type,,Button,Column,Thin-Flexure Load Cells Weighing Load Sensor.

directions (critical for complex loading).

✔ Compensates for off-axis loading errors (improves accuracy).

✔ Suitable for dynamic & non-uniform stress fields.

✔Lead Wires.

✔Wires factory-soldered to the gauge.

✔Use Case: Quick installation.

✔Pros: Easy to connect, reduces soldering errors.

✔Cons: Less durable in harsh environments.

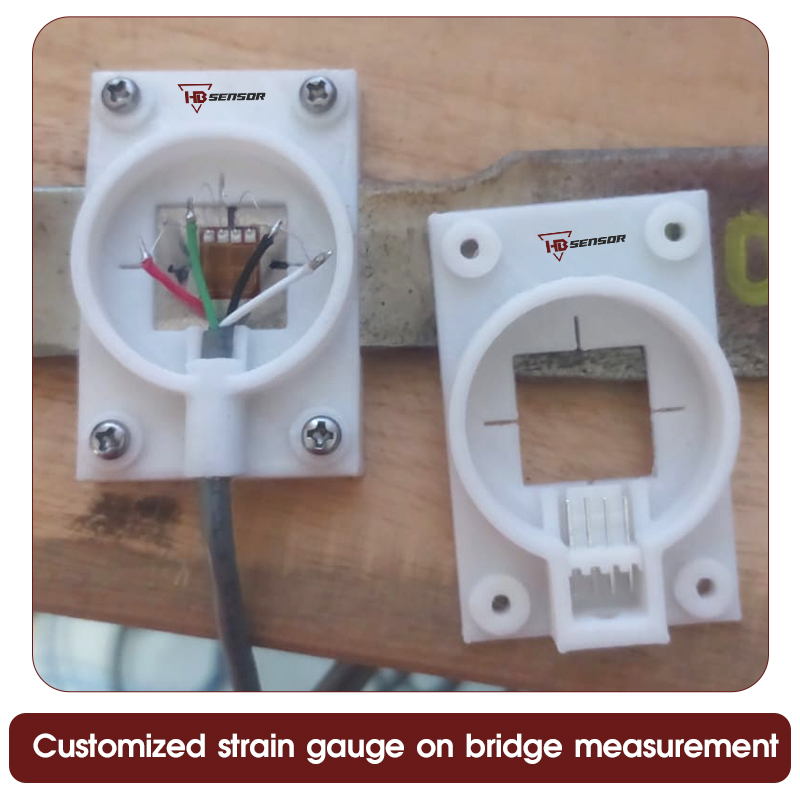

Strain gauges can be applied in a wide range of scenarios, and most of them are used in various types of force-measuring sensors. For each different type of load cell, the model of the strain gauge used also varies. You can refer to the corresponding types mentioned above. There are also specially customized strain gauges that can be used in different force-measuring scenarios. Please refer to the following cases

A foil-type strain gauge was utilized on railway tracks to assess structural integrity and analyze stress levels. This device captures track deformation resulting from train movement, offering real-time insights into strain, load patterns, and possible fatigue damage. Such data supports proactive maintenance strategies, enhancing safety and improving track efficiency. The solution is economical, robust, and compatible with wireless communication systems for distant monitoring.

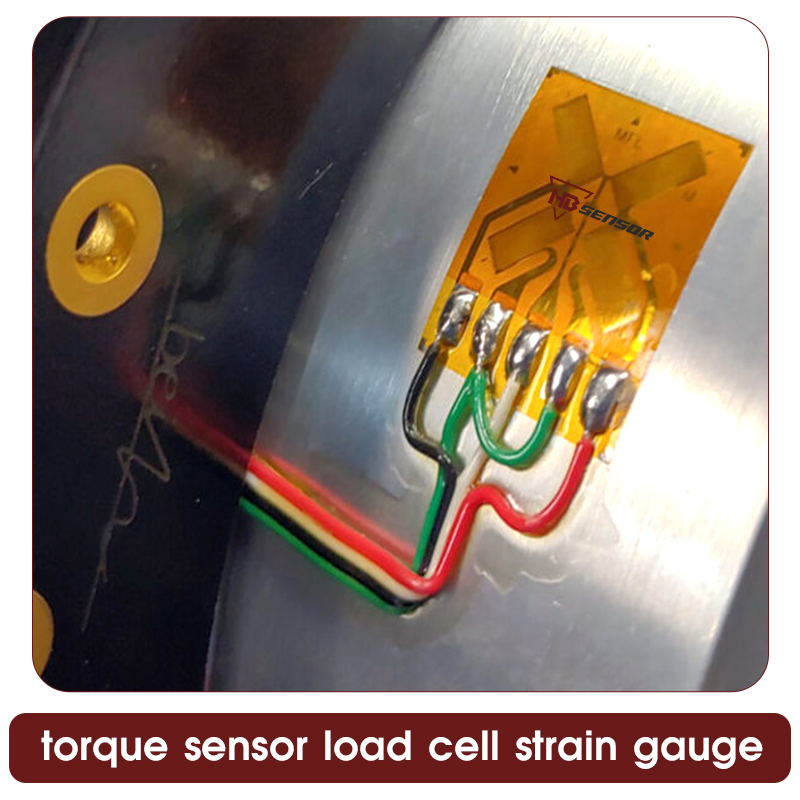

A customized foil-based strain gauge was developed for use with bending torque sensors and curved steel structures to monitor strain under varying dynamic loads. The gauge features a precisely engineered pattern that conforms to curved geometries, allowing for precise strain measurement in components such as rotating shafts, crane booms, and load-bearing beams. Advantages of this design include enhanced responsiveness to bending stresses, thermal stability, and reliable operation in challenging environmental conditions. The collected strain data contributes to better load management, structural integrity preservation, and increased safety across industrial and mechanical applications.

A customized foil strain gauge, engineered by Haibosensor, has been created for integration with bending torque sensors and curved steel elements to assess strain under dynamic loading conditions. This gauge incorporates precise patterning technology that allows for accurate strain measurement on intricate surfaces, including rotating shafts, crane booms, and structural beams. It offers excellent sensitivity to bending stresses, built-in temperature compensation, and strong resistance to harsh environmental factors, ensuring consistent and dependable performance.

The Haibosensor system supports continuous strain monitoring, which facilitates improved load management, minimizes the risk of structural damage, and boosts overall safety in industrial and mechanical setups. For those seeking a comparable application example, this case study can provide valuable insights and guidance.

HAIBOSENSOR Factory offers specialized ODM/OEM custom strain gauge services for torque wrenches and various other measurement tasks. Our team of professionals carefully bonds foil strain gauges to guarantee precise torque readings and reliable performance evaluation. Require strain gauge solutions for your application? HAIBOSENSOR is equipped to manage both the bonding process and testing procedures on your behalf!

HAIBOSENSOR provides specialized strain gauge application services for athletic gear. Our skilled technicians accurately attach foil strain gauges to assess force, stress levels, and overall performance in the following sports equipment:

– Golf clubs

– Bicycle frames

– Tennis rackets

– Fitness apparatus

HAIBOSENSOR focuses on high-accuracy strain gauge integration for a wide range of weighing and force sensing applications, such as:

Application Areas:

– Single-point load cells

– Beam-style load cells

– Compression and tension sensors

– Industrial weighing setups

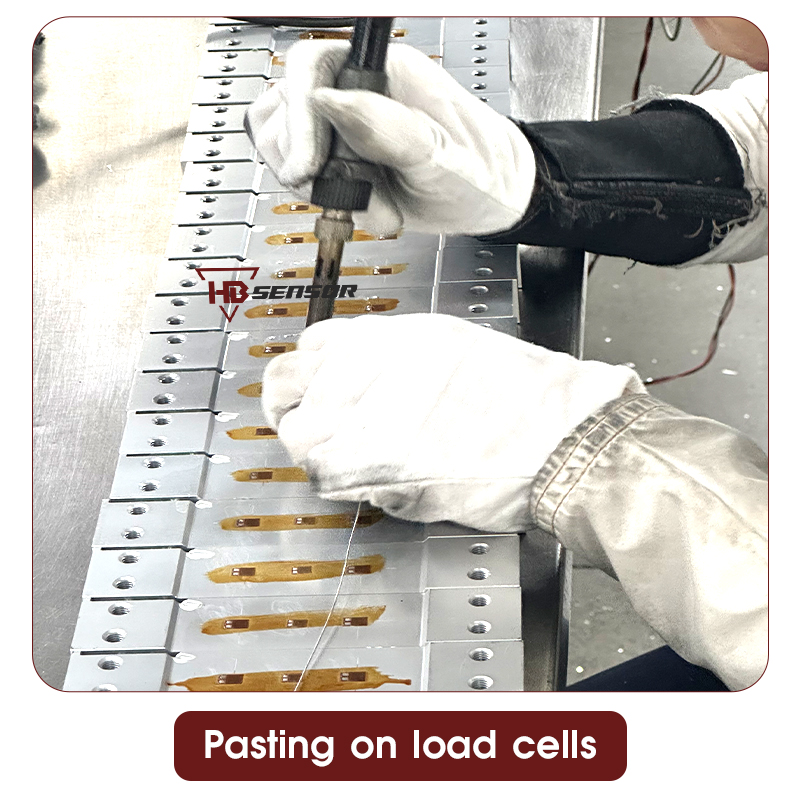

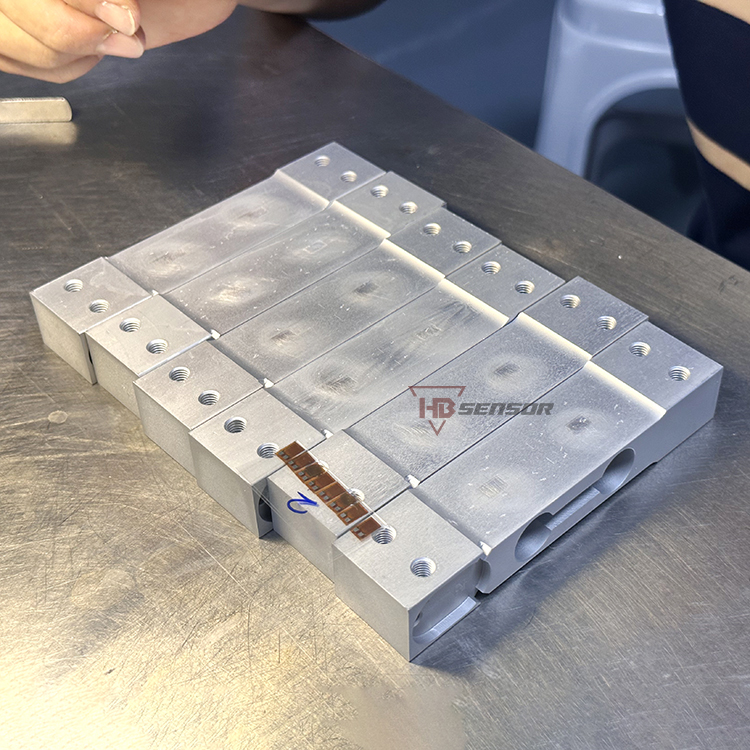

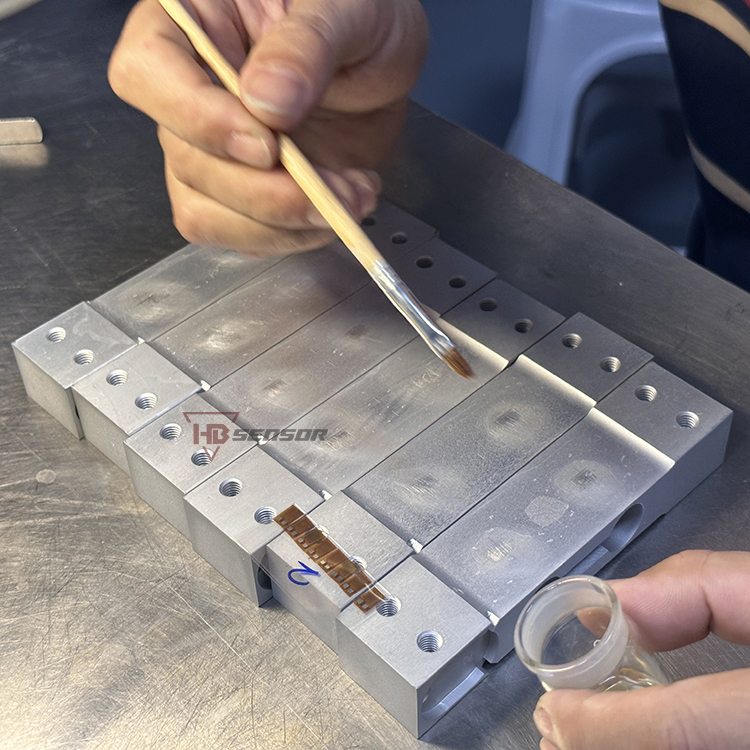

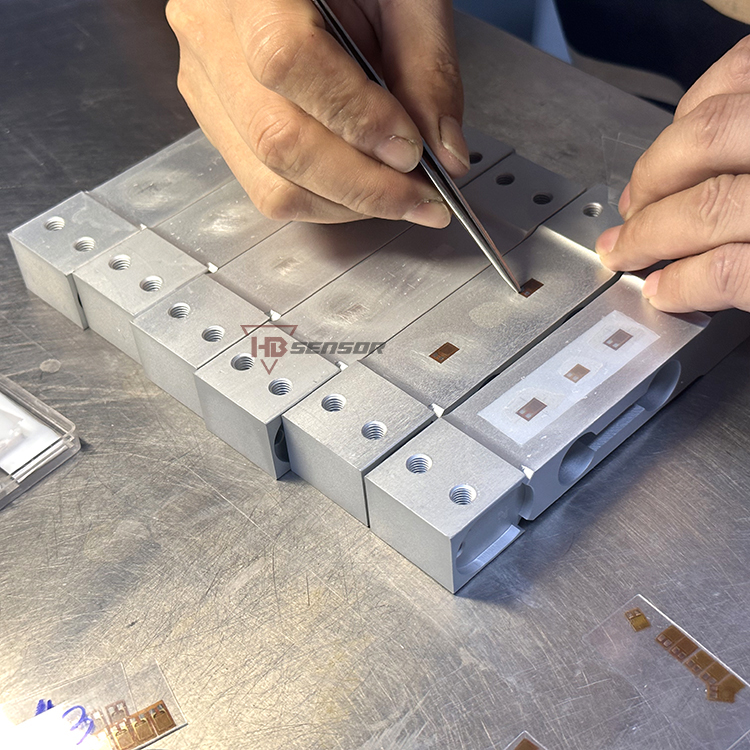

This is an operation manual for the strain gauge used by HaiBO Sensor Company. The strain gauge is the core component of the weighing sensor. However, it is also a very important process to properly attach the strain gauge.

Completely clean the designated area on the specimen surface. Utilize a solvent such as acetone along with abrasive paper or a surface conditioning pad to eliminate paint, rust, grease, and oxide layers. The objective is to achieve a contaminant-free surface with slight texture to ensure strong adhesive bonding. Following surface abrasion, re-clean the area using solvent and a lint-free wipe, repeating the process until no traces of residue are visible.

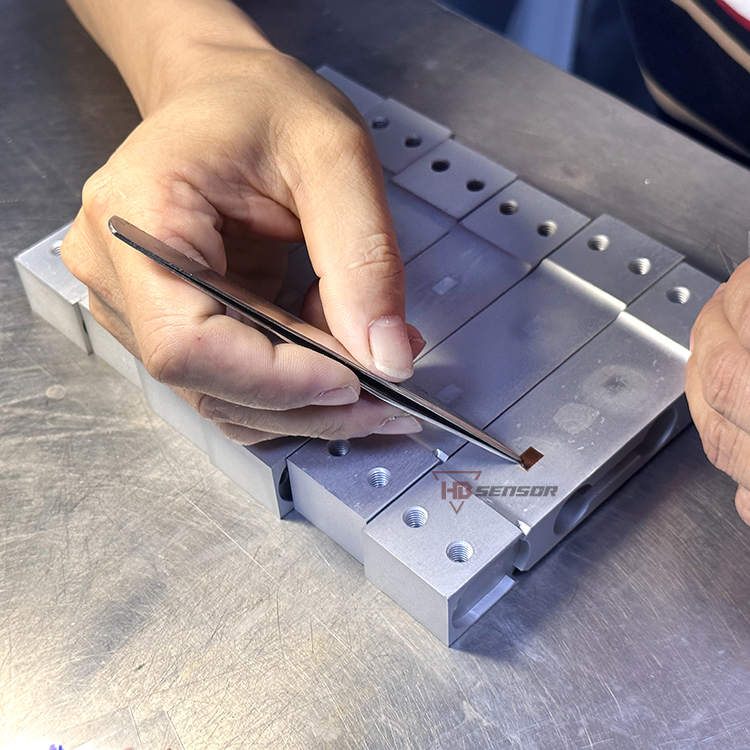

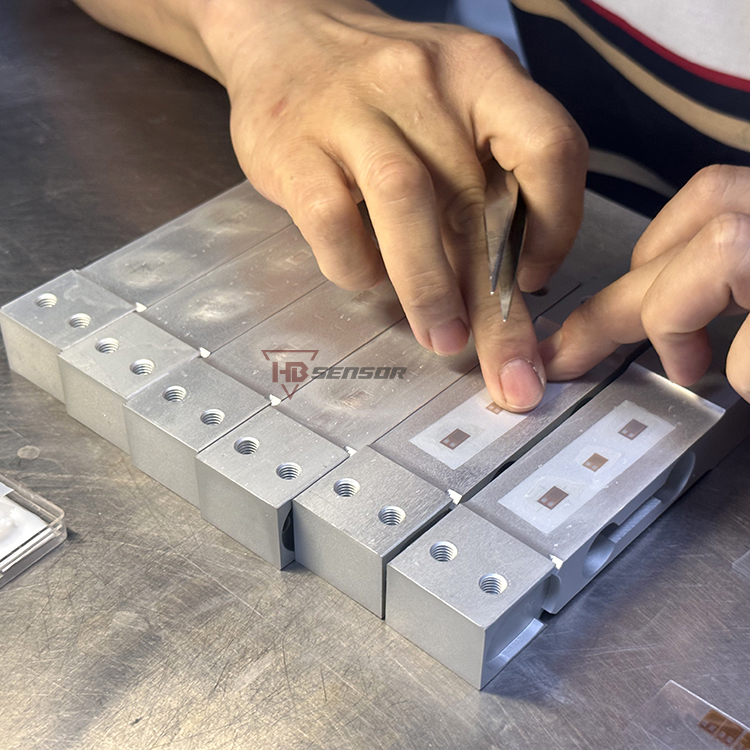

Unpack the strain gauge with care. Using precision tweezers, carefully position it on a clean, flat surface to examine for any physical defects. Locate the alignment indicators to confirm proper orientation during installation for accurate measurement.

Apply an even layer of the specialized H610 patch adhesive onto the prepared surface of the load cell material.

Using tweezers, carefully pick up the strain gauge. Align it precisely in the desired location and orientation on the specimen. Gently place it onto the adhesive-coated area.

After the strain gauges are attached, we need to make a slight adjustment to their positions to ensure that they are within the marked area of the elastomer material.

Place a thin piece of non-stick release film over the back of the gauge. Using a soft rubber roller or your finger (with a finger cot), apply firm, rolling pressure from the center of the gauge outward. This squeezes out excess adhesive and ensures a thin, uniform bond layer without air bubbles. Hold the gauge in place for the adhesive’s recommended initial set time

The strain gauges of Haibosensor are customizable. However, which specific parts can be customized? If you are also looking for a professional manufacturer of strain gauges that can offer customized products, please contact me at HAIBOSENSOR!

If you’re looking for a strain gauge but aren’t sure how to choose the right model, you can refer to our example part numbers for guidance. :BF350-3AA-11-T0-W-X:

BF:Foil Material

350:Resistance (500,1000,2000)

AA:Type:Linear Single Strain Gauge

11:(Steel) 23(Aluminium Alloy)16(Alloy Steel)

T0:Temperature self-compensation

W:Welding Wire:Sliver,Enameled Wire,Cable.

X:Wire Length

We provide custom strain gauge services, such as welding wires according to customer requirements, including wire length, type, and connection to terminals. We can also offer free samples. If you have any custom strain gauge projects, feel free to contact our HaiboSensor team!

Feature and use The H-610 strain gauge adhesive includes two components epoxy adhesives with small creep and hysteresis, good repeatability, wide temperature range , low viscosity, short pasting cycle and convenient use etc. it is recommended for high.precision sensors.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.