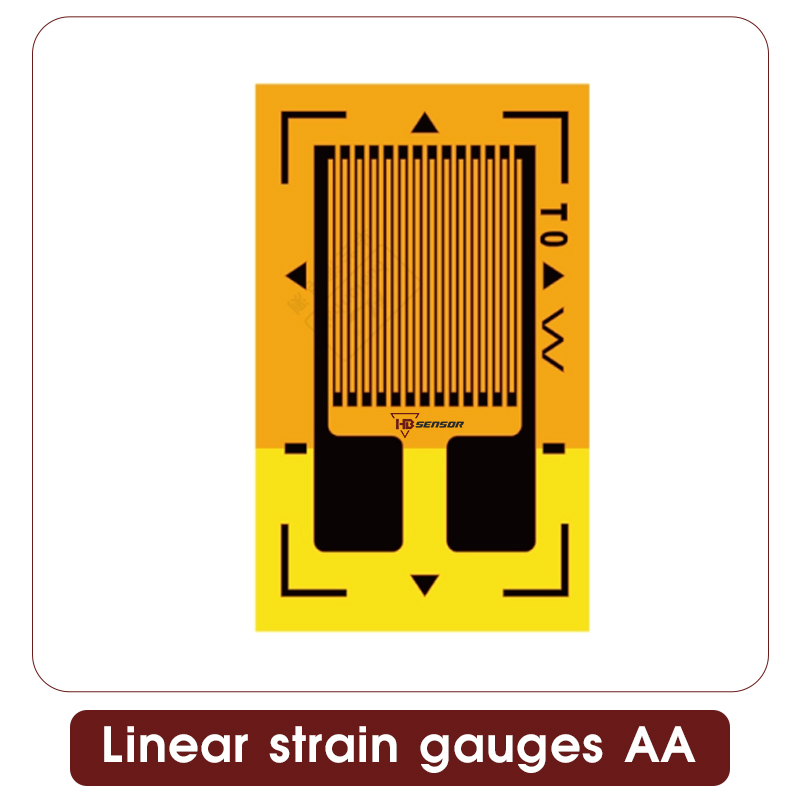

The BF350-3AA-23-TO is a high-performance foil strain gauge engineered for design engineers and application technicians who require dependable, accurate strain measurement in demanding environments. Its precision uniaxial sensing capability makes it an ideal, off-the-shelf solution for integrating into load cells, pressure transducers, and force sensors—especially where consistent performance under varying conditions is critical.

Metal foil resistance strain gauges are the core sensing elements of various strain sensors. A foil strain gauge is a thin, flexible sensor that measures strain on an object. It consists of a metallic foil pattern mounted on a backing material. When the object deforms, the foil’s electrical resistance changes proportionally, allowing precise measurement of stress, load, or pressure.

Key Features & Advantages

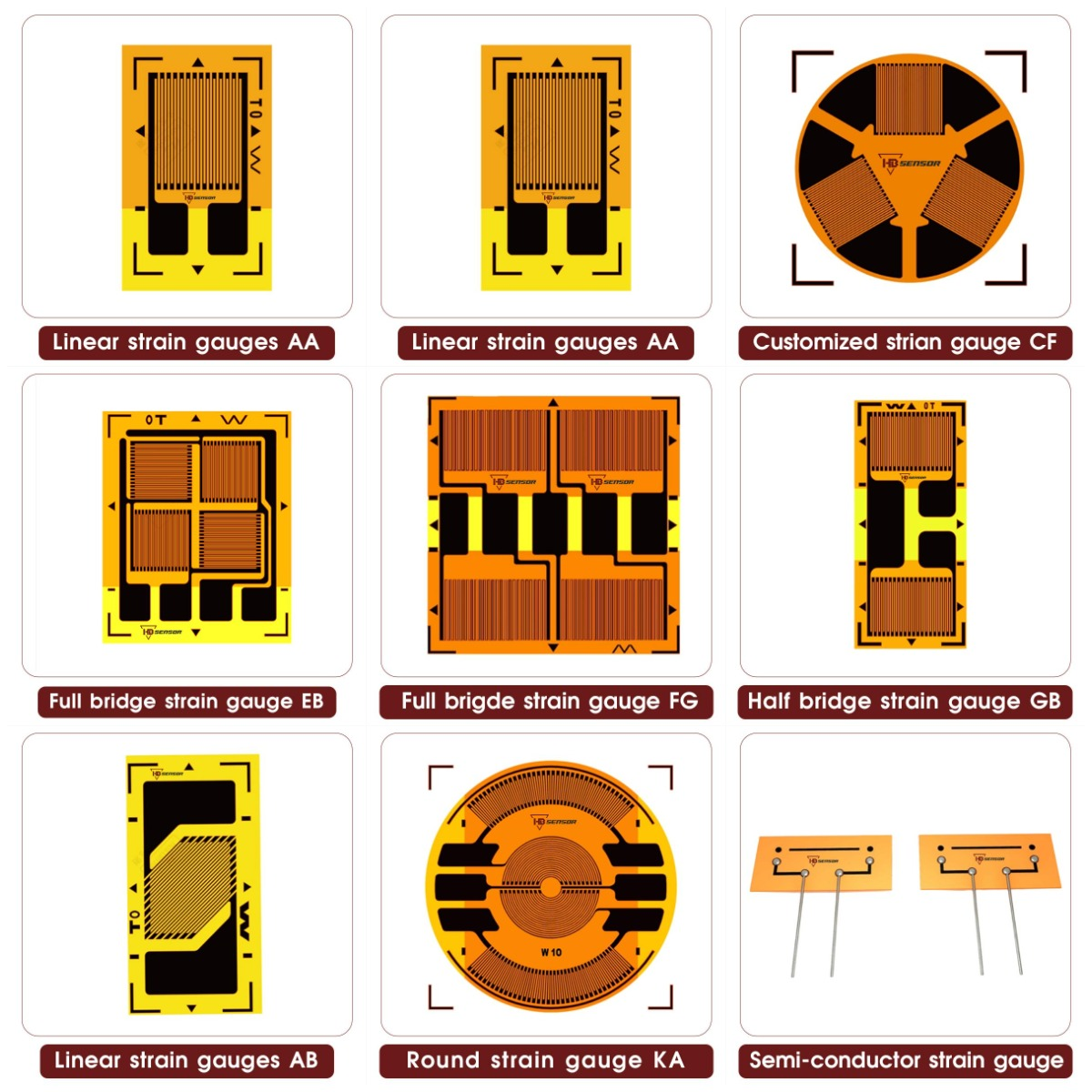

HaiboSensor’s resistance strain gauges have a development history of 25 years. These strain gauges are categorized into industrial precision strain gauges and consumer-grade strain gauges. Precision strain gauges use imported foil materials and undergo strict heat treatment processes, with modified phenolic resin substrates. They can achieve sensor creep, hysteresis, and temperature performance within 0.007%. Consumer electronics strain gauges offer high production capacity and cost-effectiveness.

Our foil AA single axle strain gauges products are crafted from high-quality imported foil materials, ensuring reliable and consistent performance. We have established long-term partnerships with many leading companies, and our products are successfully serving markets across Europe, the USA, Iran, Turkey, and beyond. We offer customized strain gauge solutions, including tailored dimensions, resistance specifications, operation at temperatures up to 200°C, adjustable weld wire lengths, and various cable options. Additionally, we support ODM/OEM services and can assist customers with mounting strain gauges directly onto their projects. If you have any inquiries about our strain gauges, please feel free to reach out to our team—we’d be delighted to help. Of course, we’re happy to provide free samples upon request!

Foil technology – High accuracy and stability

Standard specs – 350Ω-2000Ω, gauge factor 2.3

Polyimide base – Heat-resistant and flexible

Wide applicability – For various stress tests

| 参数项 / Parameter | 规格值 / Specification |

|---|---|

| 型号 Model | BF350-3AA-23-T0 |

| 电阻值 Resistance | 350 Ω ± 0.1% |

| 栅丝尺寸 Gage Length | 3 x 2 mm (长 x 宽 / Length x Width) |

| 基底尺寸 Grid Size | 8 x 5 mm (长 x 宽 / Length x Width) |

| 基底材料 Base Material | 聚酰亚胺 / Polyimide |

| 引线类型 Lead Type | 镀锡铜线 / Tinned Copper Wire |

| 引线数量 Leads | 3 线制 / 3-Wire |

| 灵敏度系数 Gage Factor | 2.0 ± 1% |

| 热输出系数 Thermal Output | ≤ 1.5 µε/°C |

| 工作温度范围 Operating Temp. | -30°C to +70°C |

BF350-3AA-23-TO strain gauge is ideally suited for bonding onto the engineered elastic elements of various load cells. Its small size and 3-wire capability make it a prime choice for the following common types:

Bending Beam Load Cells

Shear Beam Load Cells

Shear Beam Load Cells

Low-Capacity S-Type Load Cells

Miniature or Sub-Miniature Load Cells

HaiboSensor The BF350-3AA foil strain gauge functions as a highly adaptable key element in numerous force measurement systems. It plays an essential role in various weight sensing technologies, such as Cantilever Beam, Double Parallel Beam, and S-Type sensors. In addition to its use in weighing applications, this strain gauge is widely employed in material testing equipment, torque detection for engine performance analysis, hydraulic pressure transmitters, and structural health assessment of vital infrastructures including bridges and transmission towers, highlighting its significance in accurately measuring force, pressure, and mechanical stress.

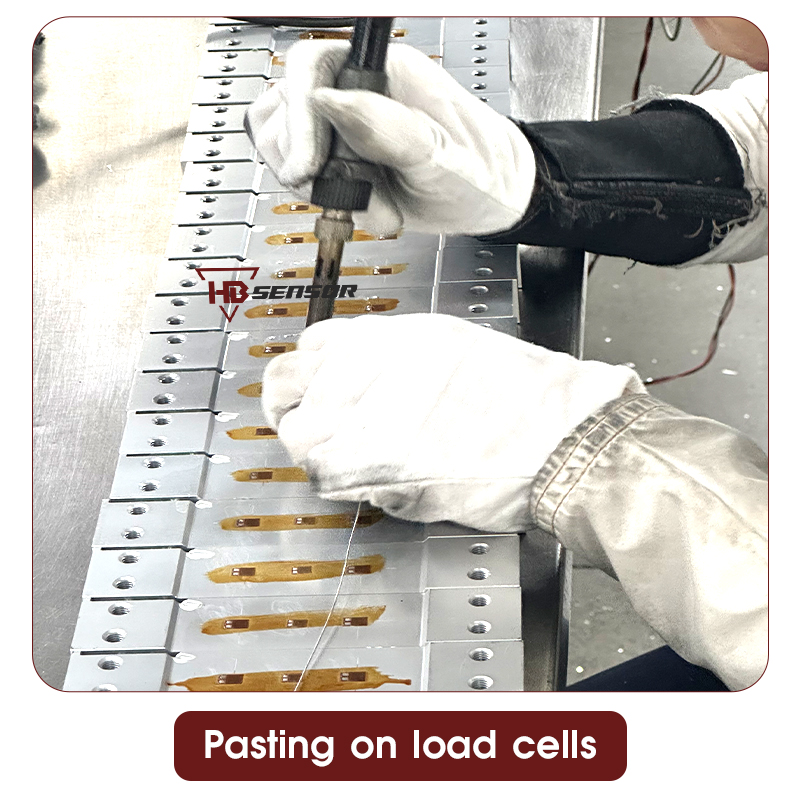

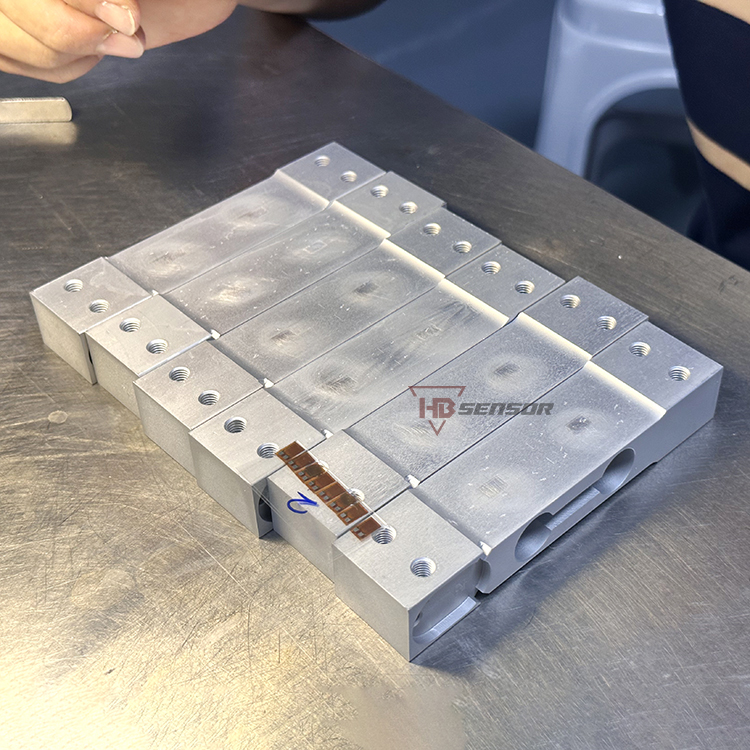

This is an operation manual for the strain gauge used by HEBO Sensor Company. The strain gauge is the core component of the weighing sensor. However, it is also a very important process to properly attach the strain gauge.

Completely clean the designated area on the specimen surface. Utilize a solvent such as acetone along with abrasive paper or a surface conditioning pad to eliminate paint, rust, grease, and oxide layers. The objective is to achieve a contaminant-free surface with slight texture to ensure strong adhesive bonding. Following surface abrasion, re-clean the area using solvent and a lint-free wipe, repeating the process until no traces of residue are visible.

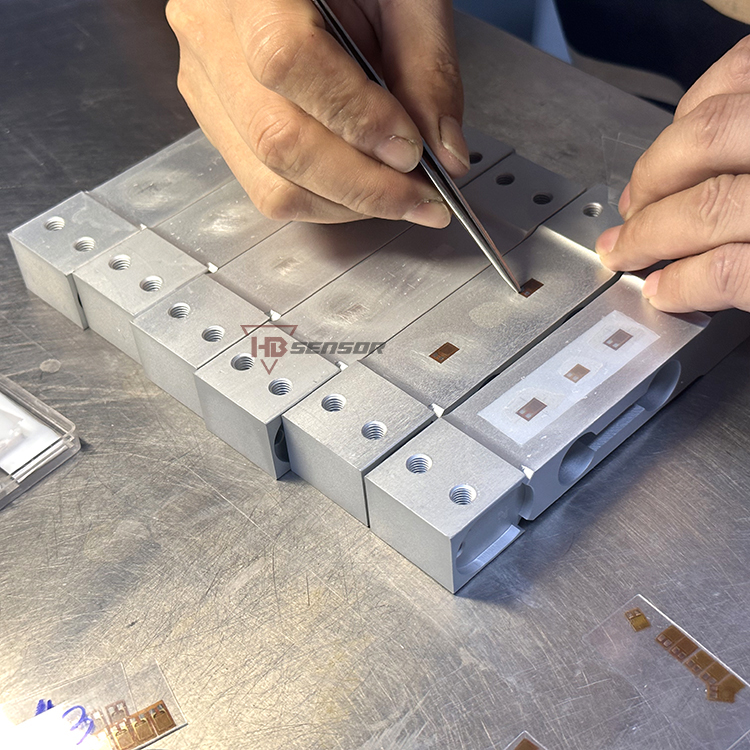

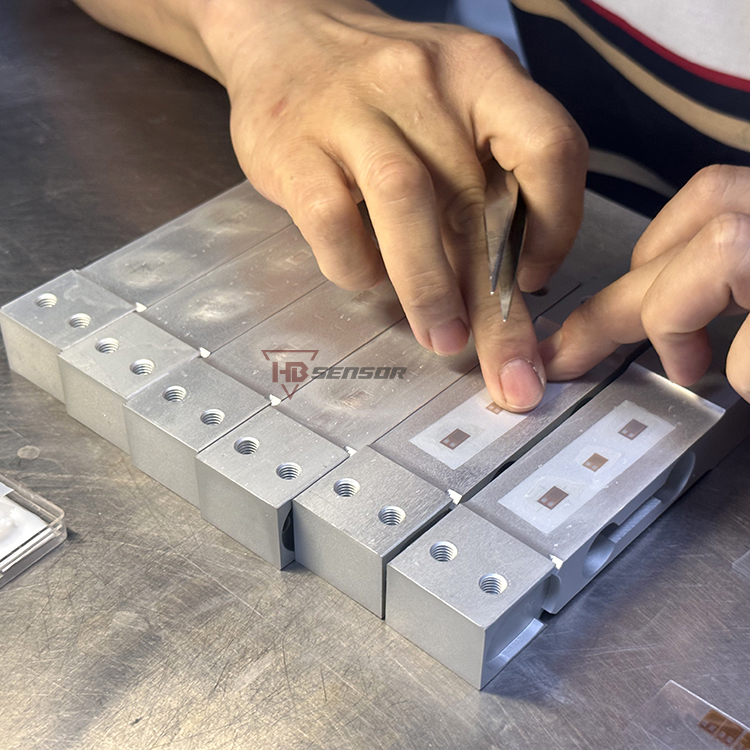

Unpack the strain gauge with care. Using precision tweezers, carefully position it on a clean, flat surface to examine for any physical defects. Locate the alignment indicators to confirm proper orientation during installation for accurate measurement.

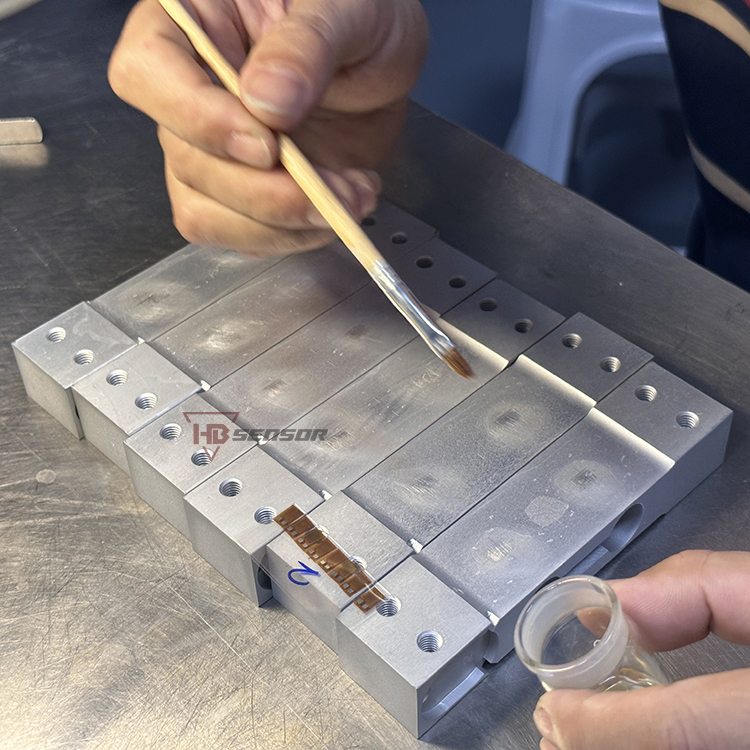

Apply an even layer of the specialized H610 patch adhesive onto the prepared surface of the load cell material.

Using tweezers, carefully pick up the strain gauge. Align it precisely in the desired location and orientation on the specimen. Gently place it onto the adhesive-coated area.

After the strain gauges are attached, we need to make a slight adjustment to their positions to ensure that they are within the marked area of the elastomer material.

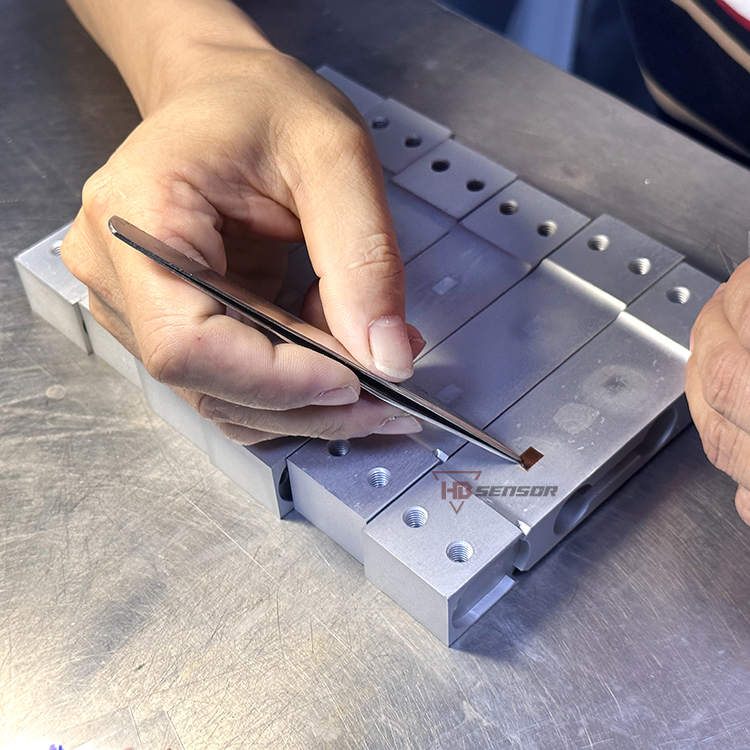

Place a thin piece of non-stick release film over the back of the gauge. Using a soft rubber roller or your finger (with a finger cot), apply firm, rolling pressure from the center of the gauge outward. This squeezes out excess adhesive and ensures a thin, uniform bond layer without air bubbles. Hold the gauge in place for the adhesive’s recommended initial set time

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.