An aluminum load cell is a force-measuring component whose core sensing element—the elastic body—is precision-machined from high-strength aluminum alloy. As the name suggests, this material gives it distinct advantages over traditional steel load cells, notably light weight, high response speed, and excellent fatigue resistance.

As a professional manufacturer with extensive industry experience, HAIBOSENSOR specializes in providing a full range of aluminum load cell solutions. We offer various structural types and sizes, with a measuring range from 0.1 kg to 1000 kg, enabling us to meet diverse needs—from precision laboratory instruments to industrial automation production lines.

True high precision comes from inherent stability. Our aluminum load cells undergo precise temperature compensation and aging treatment, which effectively minimizes thermal and long-term drift. This ensures stable, reliable signal output over extended periods, even under demanding conditions, and guarantees performance that fully complies with the C3 international accuracy standard.

In the following sections, we will explore the core advantages and technical details of HAIBOSENSOR’s high‑precision aluminum load cells.

Crafted from high-strength aluminum alloy, HAIBOSENSOR’s single point aluminum load cells are engineered to leverage the unique advantages of this versatile material. The inherent properties of aluminum provide an exceptional strength-to-weight ratio, resulting in compact, yet highly durable and remarkably lightweight sensors designed for easy integration into space-conscious applications. This material choice ensures excellent responsiveness and fatigue resistance, making these single point load cells ideal for dynamic weighing platforms. Furthermore, protected to IP65 standards, these robust aluminum units are shielded against dust and water jets, guaranteeing reliable performance even in demanding industrial and commercial environments. The combination of precision-machined aluminum and robust sealing allows HAIBOSENSOR to deliver cost-effective, reliable, and highly accurate single point force measurement solutions. Ultimately, HAIBOSENSOR’s expertise in single point aluminum load cell design translates into optimal performance for a wide range of applications, including precision platform scales, retail scales, bench scales, and automated process control systems.

Aluminum load cells offer an excellent strength-to-weight ratio, making them both robust and easy to integrate into systems

Their material properties allow for fast response times and exceptional performance in dynamic or cyclic loading applications.

Compared to those made from stainless steel, aluminum load cells are generally more economical for a wide range of industrial uses.

With proper alloy selection and surface treatments, they provide reliable service in many non-harsh environments.

These load cells are ideal for platform scales, industrial weighing, and force measurement in packaging and automation.

They are typically suited for low to medium-capacity weighing tasks, balancing performance with economic efficiency.

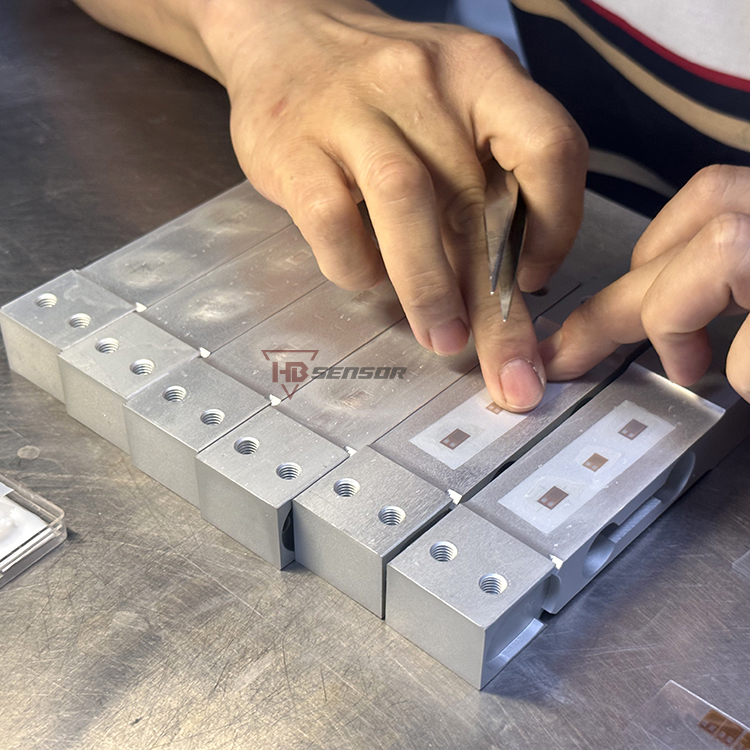

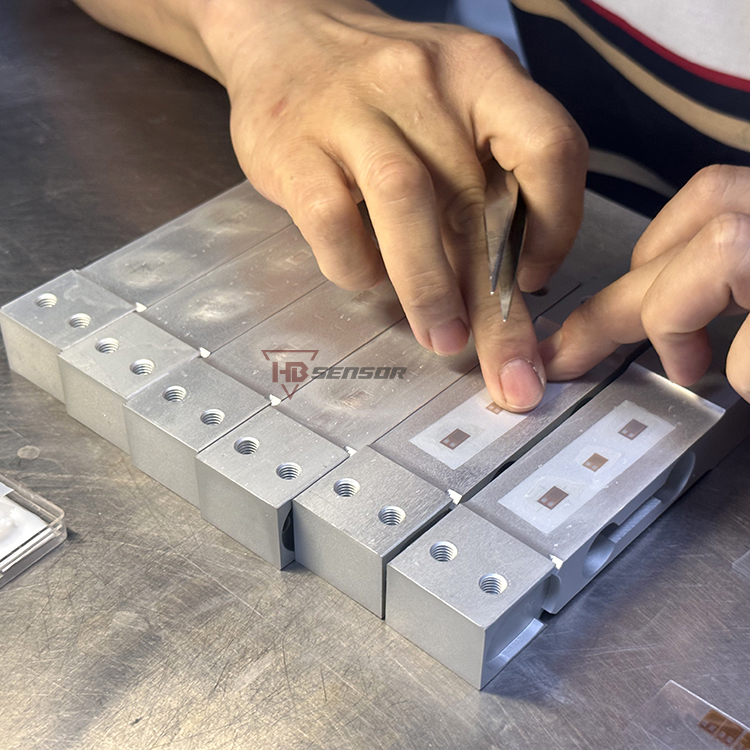

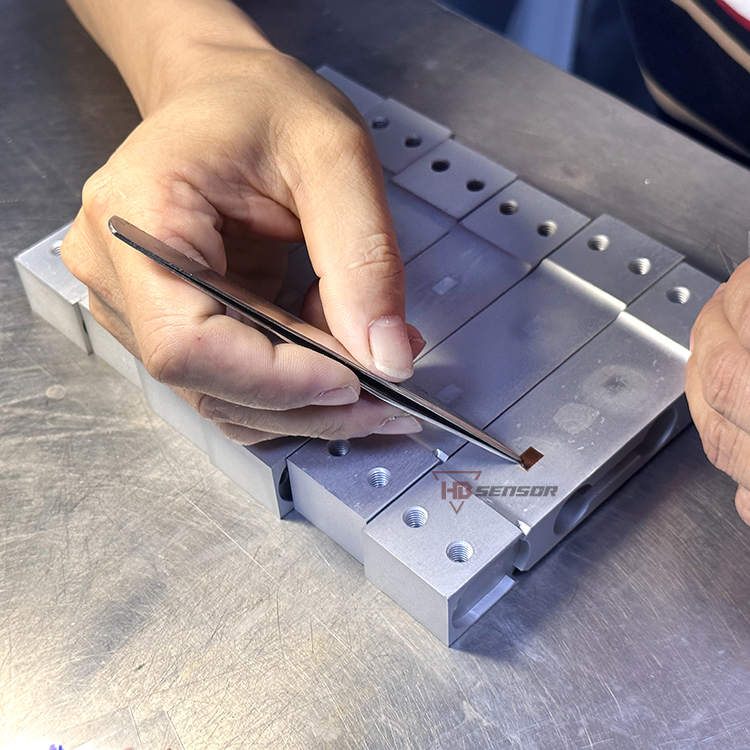

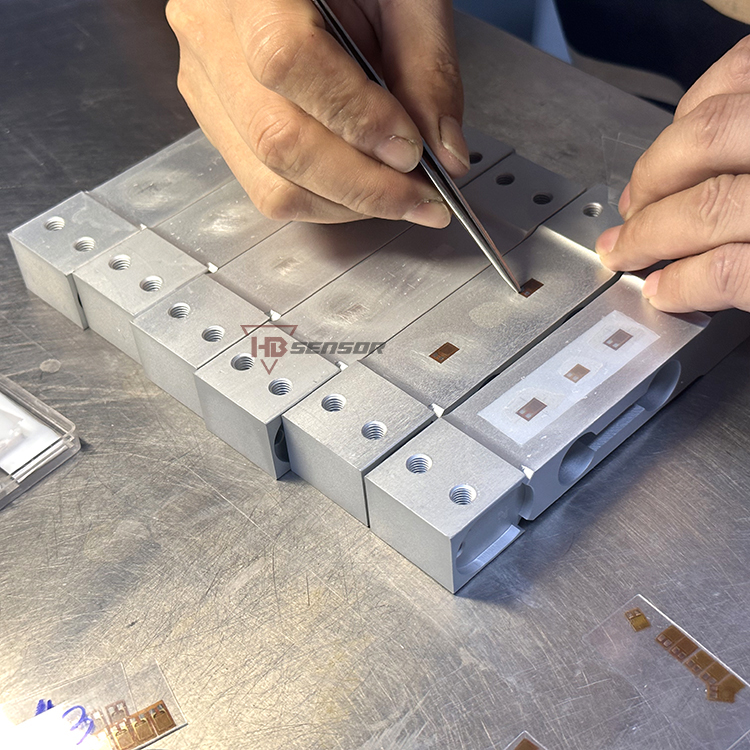

Our aluminum load cell manufacturing process is meticulously crafted to ensure outstanding performance and durability. It begins with selecting premium-grade aluminum alloys, which are precision-machined into optimized load-bearing structures. Key surfaces are then laser-marked to ensure exact strain gauge placement. Each sensor undergoes specialized corner relief treatment to eliminate stress concentrations, followed by a thorough cleaning to prepare for bonding. The strain gauges are carefully applied and thermally cured to achieve a stable, permanent bond. Next, the gauges are interconnected to form a precise Wheatstone bridge circuit. A protective sealant is applied to shield the sensitive electronics from environmental factors, before final calibration and robust packaging.

We understand that every customer’s trust is hard-earned, and each aluminum load cell we produce is built to honor that trust and support. If you are interested in aluminum load cells or believe they can enhance your product, please consult the HAIBOSENSOR team. We are committed to providing you with the optimal solution and the best value.

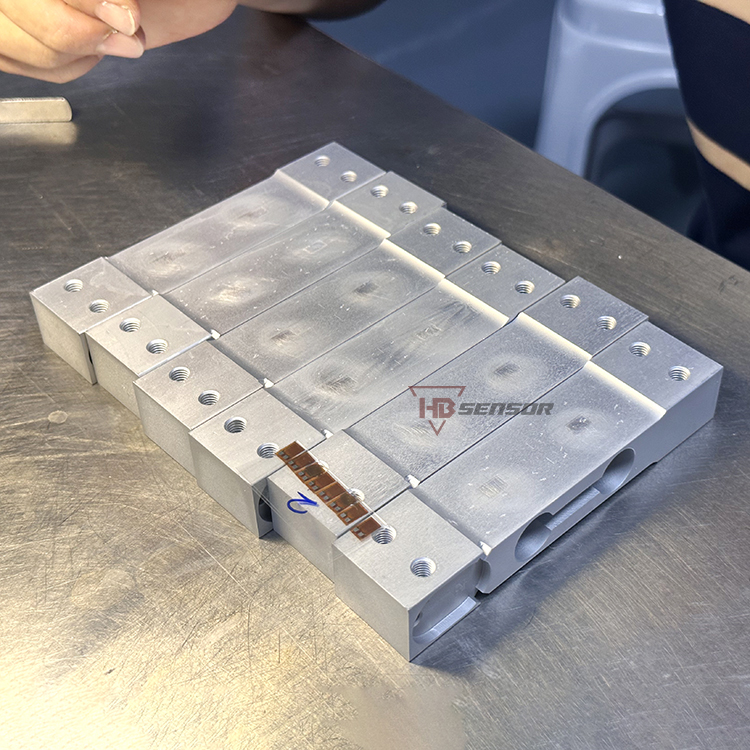

We begin with high-grade aluminum billets, which are precision-machined into the desired load-bearing structure (like a shear beam or platform sensor) to achieve the optimal geometric design.

A laser is then used to mark precise, clean areas on the aluminum body where the strain gauges will be bonded, ensuring perfect alignment and positioning.

The machined aluminum structure undergoes a specific corner relief process. This critical step involves carefully smoothing and treating the corners to eliminate stress concentrations, which is essential for linear output and long-term stability.

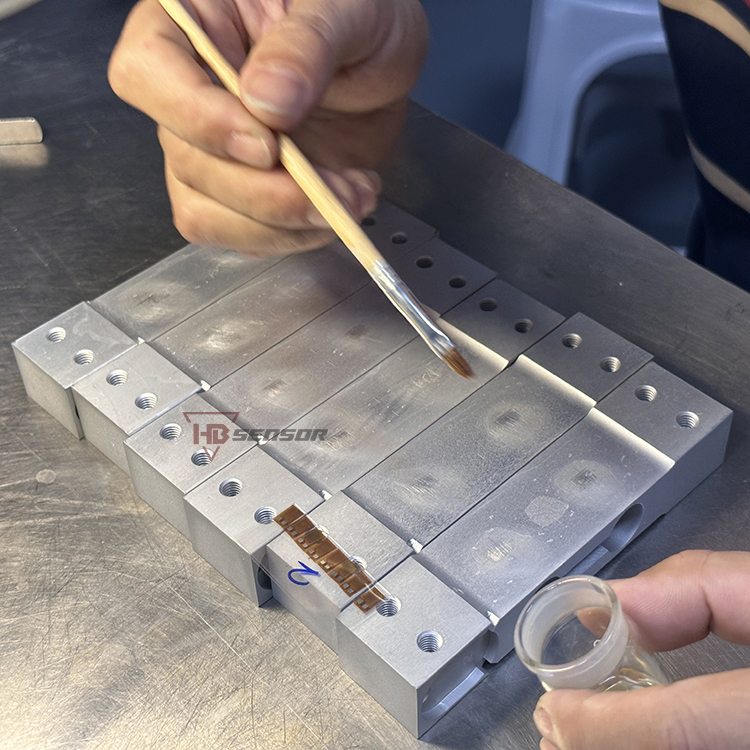

The aluminum cell is thoroughly cleaned using specialized solvents and techniques. This removes all contaminants, oils, and oxides from the marked areas, creating an ideal, pristine surface for strain gauge adhesion. The strain gauges are meticulously bonded onto the prepared areas. The entire assembly is then placed in a controlled oven or curing chamber. The heat-curing process permanently sets the bond and stabilizes the gauges.

After curing, the fine wiring process begins. The individual strain gauges are carefully interconnected to form a complete Wheatstone bridge circuit, which is the core of the sensor’s electrical signal output.

A protective sealant or gel (potting compound) is applied to the wired assembly. This crucial layer protects the delicate bridge circuit from environmental damage such as moisture, dust, and mechanical shock, thereby guaranteeing reliability.

The sensor is integrated into its housing, undergoes rigorous calibration and testing, and is then carefully packaged for shipment, ensuring it arrives in perfect condition.

Precision is quantified through an Aluminum load cell’s combined error, which is defined by its core performance parameters. The following specification set exemplifies what distinguishes a HAIBOSENSOR high-precision Aluminum load cell.

High Precision Specification Aluminum Load Cell within Range:1-50kg

The core design philosophy of these aluminum load cell to deliver reliable performance while achieving optimal cost control. They are not “low-quality,” but rather represent a precise balance between performance and price for practical, efficiency-driven applications. It is precisely because of this value proposition that high cost-performance aluminum load cells have rapidly been adopted across a wide range of smart applications in various industries, revealing immense market potential. We actively recommend these pragmatic solutions.

If you are seeking aluminum load cells where cost control is a priority, consult HAIBOSENSOR. We will provide a well-matched solution for your needs

For standard-accuracy single point aluminum load cells, key performance data to focus on include output sensitivity and zero-temperature drift. While they do not offer the same level of stability as high-precision weighing sensors, their performance is entirely sufficient for general applications and most smart device scenarios. Therefore, it is important not to assume that standard-accuracy single point aluminum load cells are merely “low-cost”single point aluminum load cells —they provide reliable functionality tailored to fit common needs.

In contrast, high-precision load cells often come with longer production cycles due to stricter manufacturing and calibration requirements. At HAIBOSENSOR, we do not simply promote one type over another. Instead, we encourage customers to consider their actual application needs when selecting a load cell—or let our team recommend the most suitable solution for your scenario.

HAIBOSENSOR’s single point aluminum load cells are the intelligent choice for modern, connected applications. Engineered for seamless integration, they empower a diverse range of smart systems where reliable, cost-effective weighing is crucial:

Their compact, lightweight aluminum design allows for easy embedding, while the IP65 protection ensures resilience against dust, moisture, and daily use across all these environments. By combining essential accuracy with exceptional durability and value, our single point aluminum load cells are the reliable foundation for the next generation of intelligent devices.

HAIBOSENSOR TEAM: Your Partner in Customized Weighing Solutions

From “Component” to “Solution”: Building It With You

The phrase “OEM & Customizable” you see is more than just a label. It represents a commitment: to transform a standard Single Point Aluminum Load Cell into a “tailor-made” core component for your product.

We understand that behind your product upgrade lies an extreme demand for precision (Accuracy), dimensions, and reliable integration. Yes, we can absolutely meet that

| Your Industry | Typical Challenge | Our Custom Solution |

|---|---|---|

| Smart Vending Machine | Irregular space at the bottom of product channels; need for vibration immunity. | Custom-shaped mounting plate; provision of a dynamic weighing algorithm package to filter interference. |

| Smart Warehousing | Pallet weighing demands high capacity, high rigidity, and long-term stability. | Custom heavy-duty structure; special processes to ensure long-term stability. |

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.