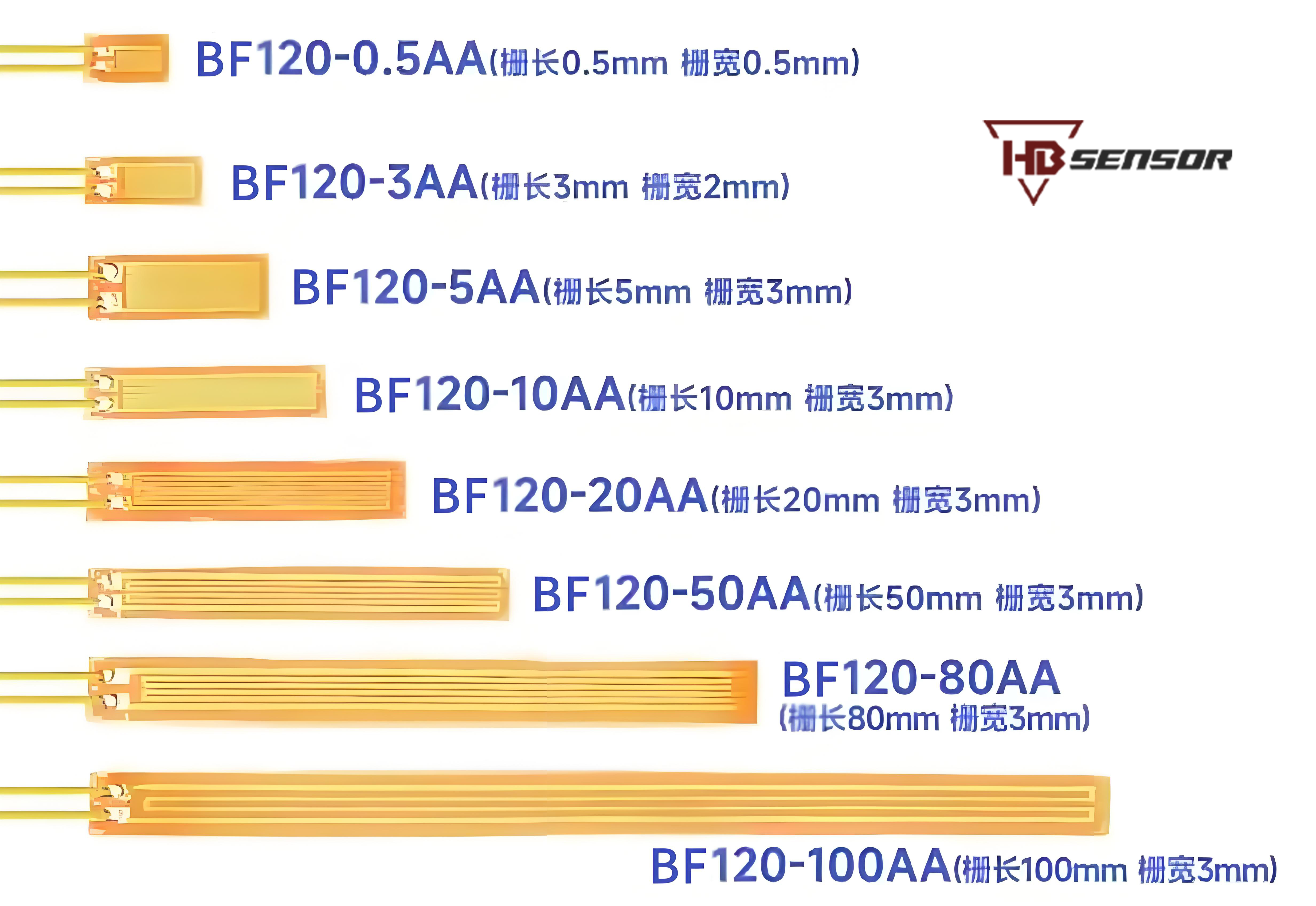

The BF series strain gauge, for measuring the axial strain and stress changes and measuring the main stress direction, is already known. (Tensile, compression, bending).

Use phenolic as a base, constantan foil as a grid, and a completely sealed structure. This design features temperature self-compensation and creep self-compensation, ensuring high accuracy and stability, making it suitable for grade 0.02 transducers.

Materials that can be measured include steel, aluminum, copper, stainless steel, carbon fiber, glass, resin, composite materials, small particle materials, wood, and concrete.

BF Series BF Series BA Series

Backing material: phenolic, modified phenolic, and Polyimide

Grid material constantan Karma Constantan (Karma)

Typical resistance 120/350/1000, 350/1000/2000, 350/1000

Average resistance tolerance ≤ ±0.1%

Typical sensitivity 2.00~2.20, 1.80~2.20, 1.86~2.20

Sensitivity coefficient dispersion ≤ ±0.1%

Strain limit 2%

Fatigue life ≥ 107 (±1000)

Operating temp. range -30~+80

Temp. self-compensation coefficient 9, 11, 16, 23, 11, 16, 23, 11, 16, 23, 27

Wire Length: Electric Cables, Silver, Enameled Wires

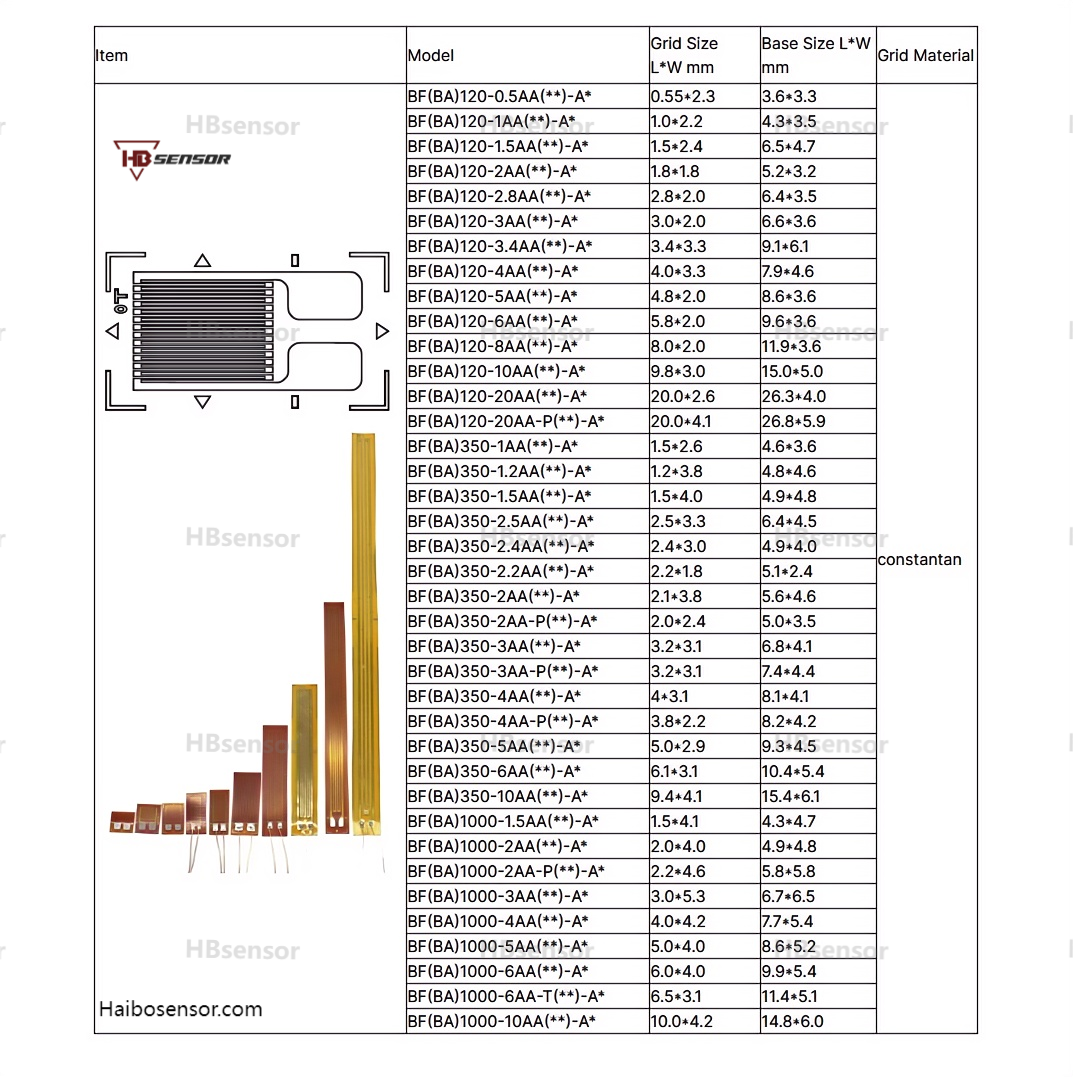

Strain Gauge Outer Size.

ODM/OEM.

Package.

|

Technical parameter

|

BF-series

|

|

Resistance

|

120/350/1000 (Ω)

|

|

Sensitivity coefficient

|

2.08±1% (A level)

|

|

Dispersion scope

|

±1%

|

|

Average output coefficient

|

1u/m/m℃

|

|

Output coefficient scope

|

50 μm/m/°C

|

|

Strain limit

|

2.5%

|

|

Fatigue life

|

≥10000000 times

|

|

Working temperature

|

-30-+80℃ -30-+150

|

|

Grid material

|

Constantan foil 40% nickel, 40% nickel, 1.5% copper, manganese alloy

|

|

Gauge base material

|

phenolic, epoxy, polyimide

|

|

Gauge base thickness

|

32±1 μm

|

|

Self-compensation

|

Temperature self-compensation and creep self-compensation

|

|

Temperature self-compensation coefficient

|

9, 11, 16, 23, 27

|

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.