The HaiBo torque sensor is an essential measuring device that is vital for industrial automation and monitoring mechanical equipment. Torque sensors are categorized into two main types: static and dynamic, based on their working principles and application scenarios. These sensors convert the torsional force of machinery into electrical signals, enabling highly accurate measurements.

Contact Us

Products

Blogs

The Haibo torque sensor is a tool that measures the amount of rotational force, or torque, being applied to something. It converts that mechanical force into an electrical signal so you can monitor and control it more accurately. You will find these sensors in cars, factories, and robots.

You may know there are two types of Strain Gauge Torque Sensors on the market for different uses. They are Static Torque Sensors and Dynamic Torque Sensors. Below, we will have some short advice to tell you about the difference between these two types so you can choose the correct one for your business.

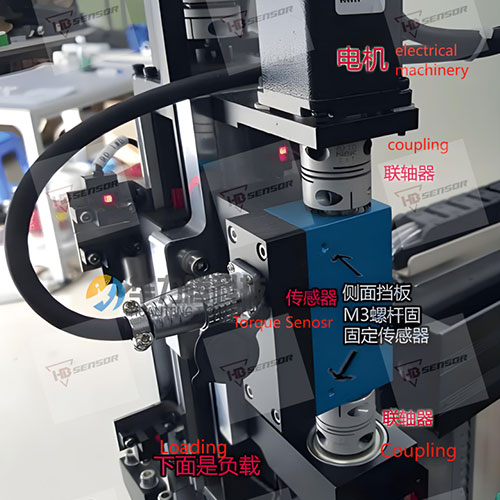

Static sensors measure torque under stationary or very low speed (<1 RPM) conditions, commonly used for screw tightening, valve testing, and wrench calibration.

Dynamic sensors measure rotating shaft torque with speeds up to 50,000 RPM, suitable for motor, gearbox, and fan main shaft performance tests. For technical details or a quote, contact HAIBOSENSOR anytime.

Micro Load Cells are categorized into Half-Bridge and Full-Bridge types. The selection between these two types typically depends on specific product requirements, installation dimensions, and customer-defined precision standards. Additionally, Micro Load Cells are manufactured using two primary materials: manganese steel and aluminum.

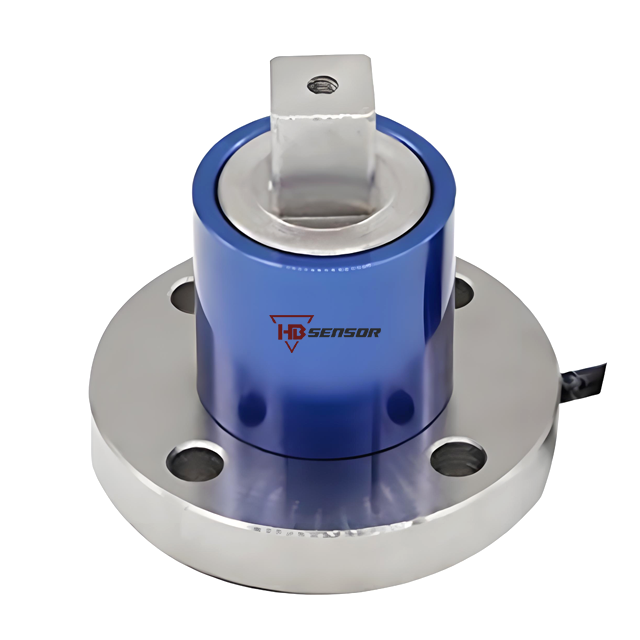

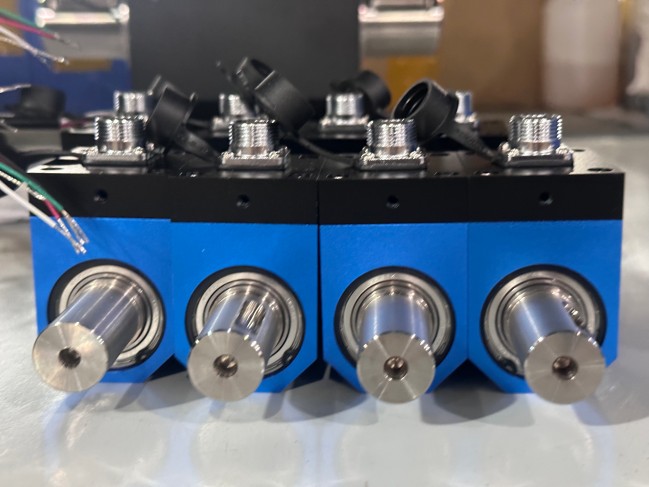

Fixed via flange bolts, high rigidity Flange Mount Torque Sensor, is one kind of mounting method of the torque sensors

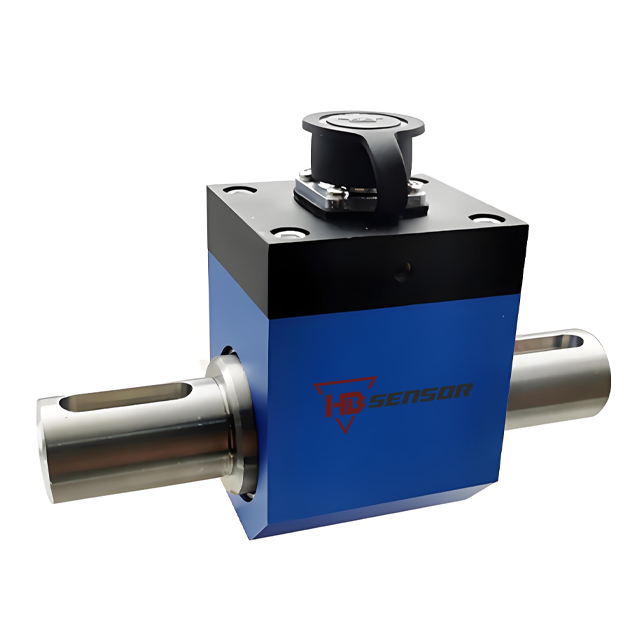

You will find that both ends are designed as smooth shafts and require the use of couplings for proper connection.

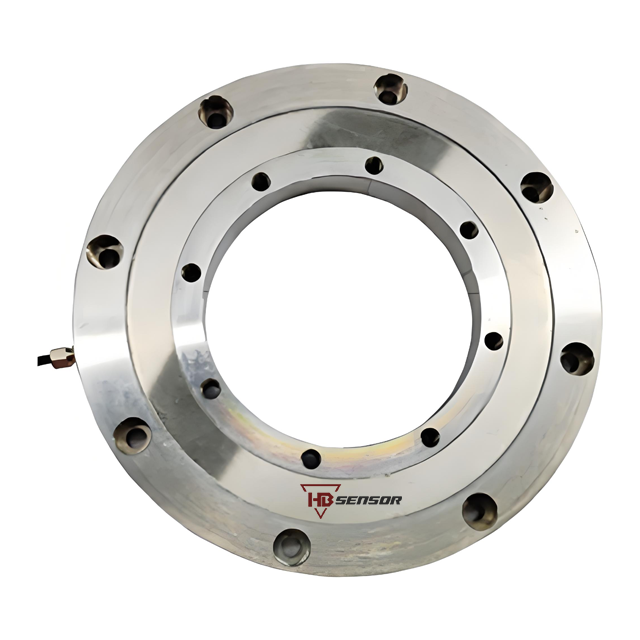

Central hole for cables/pipes, so we can all this type of the torque sensor “Hollow Shaft Torque Sensor” for daily use.

Static torque sensors paired with torque wrenches are used for high-precision tightening control and torque verification, ensuring fasteners meet standards

Each HAIBOSENSOR product reflects our commitment to technological excellence and meticulous craftsmanship, ensuring unparalleled measurement precision that honors our clients’ trust

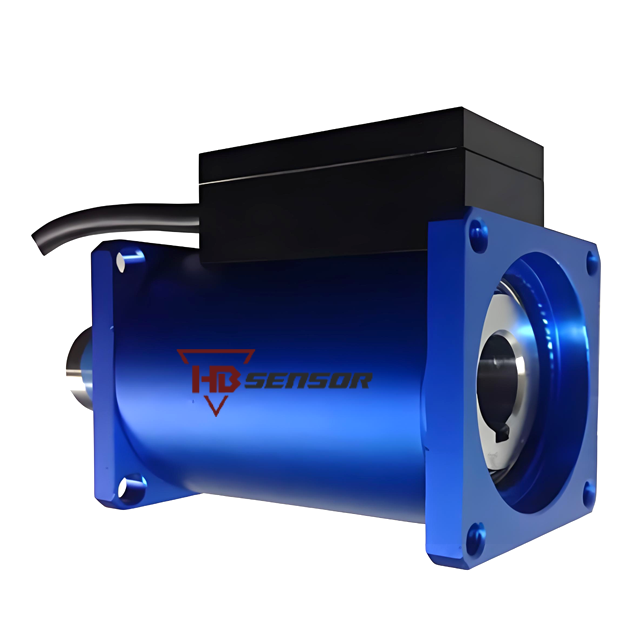

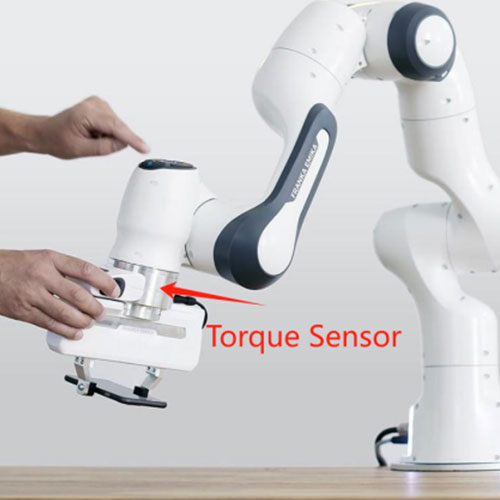

The dynamic torque sensor is a super-accurate tool that measures changes in dynamic torque in real time for systems that rotate or twist. It works great for keeping an eye on force values when things are moving really fast or changing quickly. You’ll often find it used in motor testing, robot control, and even in aerospace power systems.

We can use the dynamic torque sensor to work in the electric vehicle motor testing as the super accurate data is necessary for electric vehicle motor testing

Torque sensor elastomers for robotic arms commonly use a spoke-type design with inner and outer hubs connected by strain beams. Four strain gauges are bonded to the beams and wired as a full-bridge circuit for torque measurement.

Offshore wind turbines during typhoon seasons experience strong wind impacts. Torque sensors monitor drivetrain loads in real time, triggering yaw control to adjust blade angles and prevent gearbox damage.

There are two types of signal transmission for the torque sensor. Divided into Signal Transmission via Carbon Brushes/Slip Rings type, we can provide both of them for you. Let us know what are the differences and advantage of them are below.

If you choose the contact type, their characteristics include: Low-speed applications: tightening machines (<1,000 RPM), teaching experimental equipment and More cost-effective, but the drawback is that replacement parts need to be changed regularly.

If you choose the non-contact type, it generally has the following features (we typically recommend non-contact types): High precision, Suitable for high-speed rotation. Long-term stable operation, no maintenance or part replacement required. High-speed/long-term operation: motor test benches (>10,000 RPM), wind power monitoring (can support speeds exceeding 20,000 RPM).Harsh environments: dust, oil contamination, high humidity (e.g., marine engines)

Maintenance-free requirements: production line equipment that cannot be shut down frequently

There are a few advice for your to choose the torque sensors if you do not have idea about selecting the torque sensor for your business.

| Dynamic Torque Sensor | Static Torque Sensor | |

| Measurement Type | Real-time varying torque (shock, vibration, acceleration) | Steady or slowly changing torque (e.g., tightening, constant speed) |

| Sampling Rate | High (≥1kHz, captures transients) | *Low (≤10Hz, for steady-state values)* |

| Typical Applications | Motor/engine testing, robotics, shock monitoring | Bolt tightening, static load testing, calibration |

| Dynamic Torque Sensors | Advantages | Applications for |

| (±10V Analog) | High bandwidth (≤10kHz), requires shielded cables | Motor/engine dyno testing, shock load analysis |

| *(4-20mA)* | *Noise-resistant, long-distance (≤100m), low bandwidth* | Industrial monitoring (e.g., wind turbines) |

| (CAN/CANopen) | Multi-sensor networking, automotive standard | EV motor testing, construction equipment |

| (EtherCAT) | Ultra-low latency, real-time control | Robotics, multi-axis motion system |

| Static Torque Sensors | Advantages | Applications for |

| *(0-5V/0-10V)* | Simple,low bandwidth | Bolt tightening, static calibration |

| *(RS485/Modbus)* | Low-speed, industrial remote monitoring | Production line QA, maintenance |

| (USB/Serial) | Plug-and-play, lab-friendly | Benchtop testing, R&D |

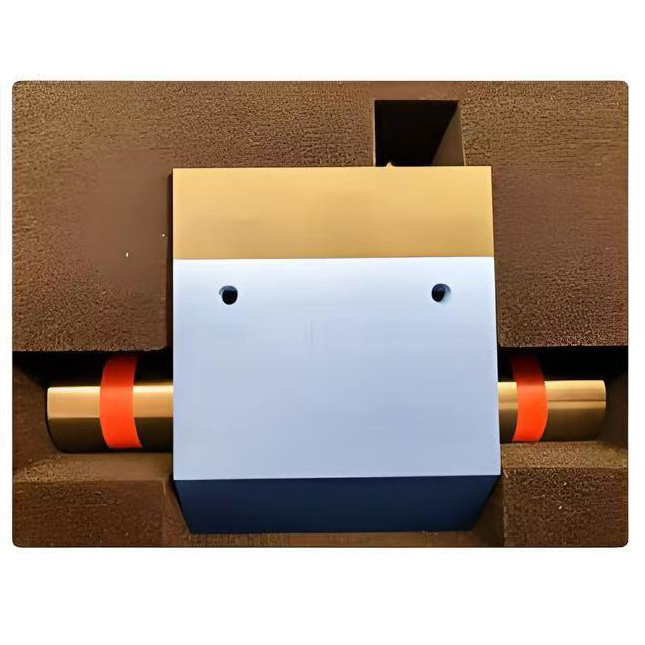

The packaging dimensions vary depending on the torque sensor model, but the attached images provide a general reference for customers. Typically, each torque sensor is individually packaged. The weight ranges based on size—for standard models, the packaging usually weighs between 1-5 kg.

If you have any demand for torque sensors, no matter Static or Dynamic types. Please contact HAIBOSENSOR. We will definitely provide all the assistance to enable your solution to achieve intelligent upgrades!

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.